Shelby Harvey, LCSW - shelby harvey

End millingprocess

End millingvs facemilling

Protective coatings, such as titanium nitride, increase tool efficiency. For example, TiAIN coated tools reduce or eliminate the need for lubrication because the coating prevents aluminum from adhering to the tool.

Endmill cutter specification

Flocculation is a process in chemistry wherein colloids are extracted from suspensions which then take the form of flake or floc. This can take place spontaneously or may be brought about by adding clarifying agents. This process is different from precipitation in the sense that before… View Full Term

End milling refers to a physical surface preparation process used to generate material chips by feeding a metal workpiece into a revolving cutter. End milling is a practical and very common procedure in industrial fabrication applications.

End millingcutter

Copyright © 2024 Corrosionpedia Inc. - Terms of Use - Privacy Policy - Editorial Review Policy

Subscribe to our newsletter to get expert advice and top insights on corrosion science, mitigation and prevention. We create world-leading educational content about corrosion and how to preserve the integrity of the world’s infrastructure and assets.

End millingmachine

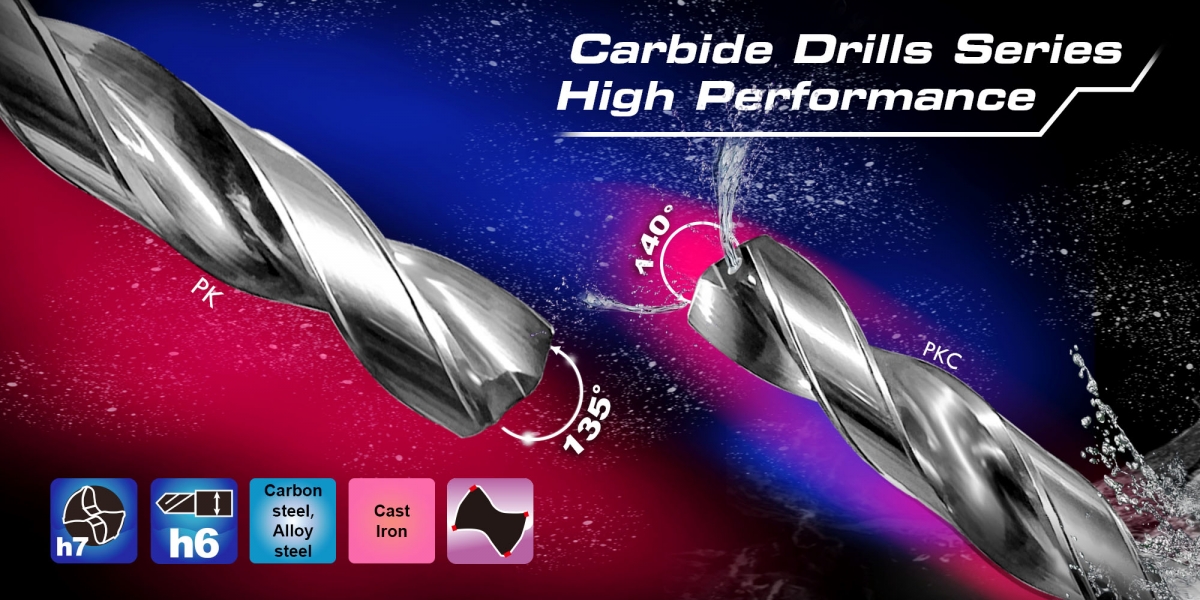

End milling is facilitated by cuts done in several directions, in contrast to the axial directional cutting that is typical of drill bits. End mills can be categorized based on the sort of tools that are affixed to them, number of flutes, helix angle, compositional material and even coating material. Specifications can vary depending on the intended purpose of the mill and the properties of the metal to be treated.

By clicking submit, you agree to receive emails from Corrosionpedia and agree to our Terms of Use & Privacy Policy.

By clicking sign up, you agree to receive emails from Corrosionpedia and agree to our Terms of Use and Privacy Policy.

By clicking sign up, you agree to receive emails from Corrosionpedia and agree to our Terms of Use and Privacy Policy.

0086-813-8127573

0086-813-8127573