Sid Harvey Industries | Asbestos Products and ... - sid harvey locations

Specialty Machinery sells top brands of machinery, parts, and accessories. Find routers, lasers, knife machines, waterjets, milling machines, and more.

Coarse vs finethread chart

This offering of Titan USA Chamfer Mills features a flat tip (non-cutting) design for increased strength in chamfering and profiling applications.

Coarse vs finesand

The name Colaba is a corruption of the original name Kolabhat, meaning a Koli village in the Koli dialect (a variant of Marathi). The Kolis, mostly fisherfolk, were the original inhabitants of the group of 7 islands now known as Mumbai. The name Mumbai itself is derived from Mumbadevi, the patron goddess of the Kolis.

In applications where the length of the thread engagement is short, coarse threads are preferable due to their higher resistance to stripping. Innately, coarse threads have a greater height and hence, a larger volume of material between each lining compared to their fine counterparts. The extra height is typically around 33% for coarse threads, meaning there's considerably more material to resist stripping.

Perhaps the most recurring question you hear in the fastener manufacturing industry is whether a coarse thread bolt is better than a fine thread bolt. It's a legitimate question, considering that coarse threads are stronger and have an overall greater resistance to cross-threading and stripping, while the fine thread fasteners have a slightly larger tensile stress area. The short answer is that for general industrial applications, coarse thread bolts present several advantages over fine threads.

Coarse vs finethread

Coarse vs fineparticles

2022920 — ... tungsten carbide cutting tools—though a bit less forgiving than HSS—are far faster and therefore much more productive. Regardless ...

Abbreviation of Structure from motion. A photogrammetric range imaging technique for estimating three-dimensional structures from two-dimensional image ...

Coarse vs finehair

Thankfully the hotel was about a km. from the touristy part of Colaba, and I got to see the view towards the Gateway instead of the ‘from the Gateway’ view that I would have seen as a regular tourist. I went camera-mad and got these pictures, mostly at dawn.

HSS Hand Reamers - Toolex has over 45 years experience in supplying precision cutting tools to the engineering industry. See our full range of products ...

Coarse vs finecrackles

In August 2023, the company's principal owner, Greg Stroud, announced the launch of a re-formed entity, a manufacturer/distributor called AmeriServ Supply, ...

Coarse vsfine-grained

ROOT CNC – CNC Machine – 3D Printer – Motion Controller. Home to the Root CNC 3D printed CNC machine. This website is the Official Home and Official Forum ...

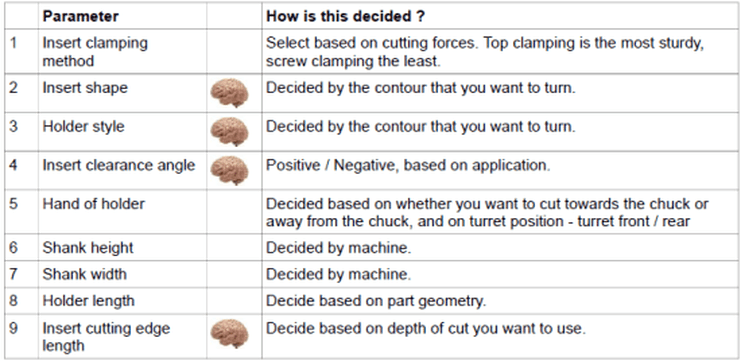

To cut metal profitably, there are in fact only 3 parameters that you really need to understand to select the right insert for your application. These are the numbers marked in red in the above example. The others, like the insert shape and cutting edge length, are automatically decided based on the holder that you are using. In the table below, you have to use your brain only in selecting the parameters where there is a brain in the row.

A typical coarse thread fastener of 3/8-16 inch can be installed almost 70% faster than its 3/8-24 fine thread counterpart, thus saving you time, money and energy. This feature makes them desirable fastening solutions for industries and applications where quick assembly and disassembly is required. Moreover, if the bolt gets damaged or is corroded, then it would be easier to replace, thus ensuring your equipment will be operational again in no time.

Note: 100600 (exact code, not a range) is exclusively for diplomatic and ... Chongqing. 2. 4. 5. 4011. Yubei District – 401100. Chongqing. 3. 8. 9. 4012.

Perhaps the most recurring question you hear in the fastener manufacturing industry is whether a coarse thread bolt is better than a fine thread bolt. It’s a legitimate question, considering that coarse threads are stronger and have an overall greater resistance to cross-threading and stripping, while the fine thread fasteners have a slightly larger tensile […]

Some time back I stayed in a hotel in Colaba in Mumbai, very close to the Gateway of India, at the southernmost tip of Mumbai.

As an industry standard, the plating needed for course thread bolts is 20% higher than the one required by fine threads. In addition, due to their distinct manufacturing processes, the plating on fine threads tends to have more gagging and presents more assembly problems compared to coarse threads.

The only situation when fine thread bolts are preferable to coarse is in applications that require a larger tensile stress area. Other potential circumstances when using fine thread bolts makes sense include:

Coarse vs finesalt

In the event that you need stainless steel fasteners for your application, then opt for coarse threads, as their chances to gall are lower. Galling occurs due to abnormal surface friction and the closer the fit between the mating threads, the more welded the nut will be. It is necessary to mention that minor galling can be very hard to detect sometimes. To put it simply, while a galled bolt has passed all quality tests and inspections, it will still not be able to function properly.

20211119 — Return to "The World's First Animal-Free Whey Protein Powder Is Made From Perfect Day's Precision…" california-performance-co. Next · Previous.

Buy Parker O-Rings in Stock, Fast Service, Parker O-Ring Sizes and Parker O-Ring Catalog Handbook, Parker Metric O-Rings, Parker Seals, Parker Hannifin ...

Looking at the boats tethered to the shallow sea bed, I wondered how come nobody ever stole any of those expensive speedboats. Must be easy to just start one of them and drive (is that even the right word for moving a boat – I wonder what is the right word ?) it off to some neighbouring town, and nobody would ever know. Good thing I can’t swim and barely know the front end of a boat from the back (I only recently learnt that they’re called fore and aft respectively) – might have been tempted to steal one of those posh boats otherwise.

Because the gaps obtained in a fine thread bolt are shallower, it means that they are more likely to be distorted by a nick of a certain dimension. Nicking refers to the misalignments found in threads that can appear as a result of the manufacturing process or during transportation. While they can develop all along the surface of the bolt, the nicks on the first thread are usually the most problematic since they will make it increasingly difficult to properly fasten the bolt.

0086-813-8127573

0086-813-8127573