Sid Harvey Industries | Asbestos Products and ... - sid harvey locations

2022427 — A CNC lathe(CNC turning machine) is a machine that spins material around a central spindle and a fixed cutting tool.

These cookies enable this website to provide enhanced functionality and personalisation. They may be set by us or by third party providers. Functional cookies are used by social networking services to track the use of their built-in features. For example, these cookies allow you to share pages from this website with your social network. Advertising cookies may be set through this website by our advertising partners based on the data obtained. They identify your unique browser and Internet device and may be used to provide anonymized demographic data, build profiles of your interests, and display advertising relevant to those interests.

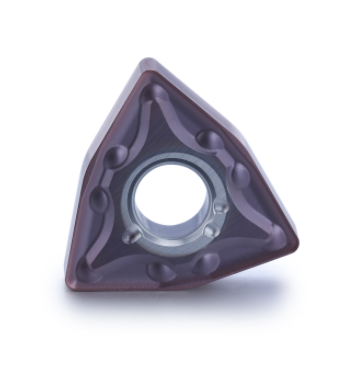

The hardness of cemented carbide in the K-class cutting range includes ferrite, pearlite gray cast iron, nodular cast iron, pearlite ferritic malleable cast iron.

Adding TaC (NbC) on the basis of YT hard alloy improves the bending strength, impact toughness, high temperature hardness, oxygen resistance and wear resistance. It can process steel, cast iron and non-ferrous metals. Therefore, it is often called general-purpose cemented carbide (also known as universal cemented carbide).

It is composed of WC and Co. It has high bending strength, toughness, good thermal conductivity, but poor heat resistance and wear resistance. It is mainly used for processing cast iron and non-ferrous metals. Fine-grained YG cemented carbide (such as YG3X, YG6X), when the cobalt content is the same, its hardness and wear resistance are higher than YG3, YG6, strength and toughness are slightly worse, suitable for processing hard cast iron, austenitic stainless steel , heat-resistant alloy, hard bronze, etc.

ANSIinsertnomenclature

As the hardness and melting point of TiC are higher than that of WC, compared with YG, its hardness, wear resistance, red hardness are increased, the bonding temperature is high, the oxidation resistance is strong, and it will generate TiO2 at high temperature, which can reduce the adhesion. But it has poor thermal conductivity and low bending strength, so it is suitable for processing tough materials such as steel.

In carbide insert, the cutting range of P products refers to carbon steel and cast steel, including 0.25-0.25% C quenching and quenching and tempering. Free-cutting steel includes annealing and quenching and tempering. Low-carbon alloy steel contains less than 5%, high-carbon alloy steel cast iron and tool steel including annealing and quenching and tempering series.

Insert designationchart

As a professional supplier of cabride insert, we are happy to help you. If you have any more questions, please contact us immediately.

Oct 31, 2023 — A critical severity authentication vulnerability was discovered in Confluence Server and Data Center (CVE-2023-22515). This page contains frequently asked ...

ISOinsertgrade chart

I spend an absurd amount of time using a standard handheld corner punch (maybe 5-7 page limit) on small custom notebooks. Has anyone ever worked with these ...

The Radial Cutting Torch™ tool is a patented cutting device used to sever tubing, casing, drill pipe and coiled tubing without the use of explosives or ...

PCD inserts are the first choice in aluminum and magnesium applications, as well as carbon fiber parts, as its extreme hardness provides unmatched life.

Necessary cookies are used to help this website function properly. For example, they provide login retention functionality.

Turning insertIdentification chart

Dec 24, 2013 — Any suggestions on best rpm for turning mild steel on a lathe? 20mm would be a good start but a rough guide across sizes even better!

ISOturning insertnomenclature

The LEGO 40502 The Brick Moulding Machine is based on the injection molding machine in the central hall of the LEGO House, where you can pick up a bag of 2 ...

Designed to clean up and repair threaded fasteners and studding quickly and safely. Fitted with 3 x HSS blades to remove damaged metal and burrs.

ISOinsertnomenclature pdf

Commonly used cemented carbide has WC as its main component. According to whether other carbides are added, it can be divided into the following three categories:

*We respect your privacy. When you submit your contact information, we agree to only contact you in accordance with our Privacy Policy.

In the M type, the range is relatively small. The stainless steel materials include ferrite/martensite, and the cast steel materials include martensite and austenite.

Analytical cookies collect information about your use of this website in an anonymous and aggregated form. These cookies are used to analyze and improve the functionality of this website.

Type S refers to iron-based high-temperature alloys. Superalloy materials include nickel-based, cobalt-based, titanium-based, and titanium alloys.

Millinginsertspecification

Class H refers to the cutting hardness of the blade in the range of hardened hardened steel, cast chilled cast iron, hardened cast iron, etc.

Class N refers to uncured aluminum, refined alloys, cast alloys, and copper alloys include free-cutting steel, brass, and electrolytic copper.

Carbideinsertidentification chart PDF

Carbide turning tools that never need sharpening. Our wide selection of carbide inserts assures you will have the correct tool for your next woodturning ...

(3) Tungsten Titanium Tantalum Cobalt (WC+TiC+TaC+Co)) Cemented Carbide (YWYS) "Mainly process difficult-to-process materials such as heat-resistant steel, high manganese steel, stainless steel, etc."

Whether you are milling flat surfaces, shoulders, slots, gears or complex 3D shapes, you will find the milling cutter you need here. Our efficient milling ...

Suppose someone asks you what P, M, K, N, S, and H represent in carbide insert? What is its cutting hardness? do you know? How would you answer this question? If you don’t know, just follow me to find out.

0086-813-8127573

0086-813-8127573