Solid Carbide Drill Bits for Stainless Steel - carbide drill through

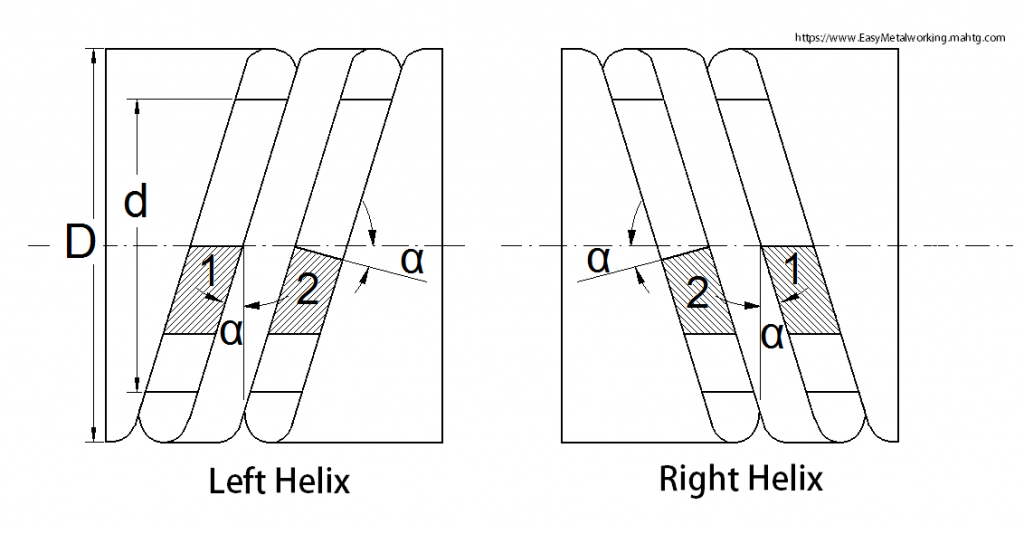

Calculate the angle of the cutting tool so that it does not damage the fillet of a single start screw, pitch 5 mm, outside diameter 25 mm and inside diameter of the screw 20 mm.

Note that these speed and feed values are guidelines assuming adequate (flooded) lubrication and workpiece stiffness. When applying oil manually (as in the lab), scale the feed and speed back to 60%, so N = 330 rpm and f = 2.0 in/min (final answer).

Hss drill speeds and feedsfor metal

D, the outside diameter of the screw, is equal to P/0.2P, is the pitch of the screw, is equal to 0.2De, is the thickness of the thread, in the screw is equal to 0.5Ph, is the height of the thread, in the screw it is equal to 0.5Pd, is the inside diameter of the screw or bottom diameter, it is equal to D-2h

TIP: Countersinking should generally be performed at 25% of the speed and the same feed per revolution as the equivalent sized drill.

Hss drill speeds and feedspdf

Next lookup the recommended feed per revolution for the drill bit in Table 2 (fr ≈ 0.004 in/rev) and calculate the feed rate using Equation 3:

First, lookup the recommended surface speed in Table 1 (V ≈ 625 ft/min) and calculate the spindle speed from Equation 2:

Every metal cutting operation requires selection of proper cutting parameters for success. As a DML TA, you need to understand basic calculations that will allow the tools you use to work as intended.

Find the angle α of the thread’s helix like this:If the thread is a single start, the following formula is used:Tan α = P/(πMd)

Example 5: Calculate the speeds for parting off 1 diameter aluminum and 1 diameter mild steel workpieces on the lathe using the standard carbide part-off inserts.

Note that these speed and feed values are guidelines assuming proper (flooded) lubrication, workpiece stiffness and depth of cut. When applying oil manually (as in the lab), scale the feed and speed back to 60%, so N = 570 rpm and f ≈ 18 in/min (final answer). Note also this problem assumes we peripheral milling versus plunge milling (since we never teach the students the latter in lab).

TIP2: Do not plunge an annular cutter at a feedrate less than 0.001 ipt (inch per tooth) in strain hardening materials like 304 stainless or titanium.

Browse a wide selection of buttress threading inserts at Alibaba.com. Find premium Terminals at reasonable prices and deals you don't want to miss.

First, lookup the recommended surface speeds in Table 1 (VALUM ≈ 625 ft/min, VSTEEL ≈ 250 ft/min (notice the 2.5 multiplier))

TIP: Plunging should generally be performed at 75% of the speed and 25% of the feedrate of the calculated peripheral cutting parameters.

Drillspeed calculator

Note: when applying oil manually, scale the feed and speed back to 60%, so N ≈ 420 rpm and f ≈ 4.8 in/min (final answer). This is close enough to 500 rpm that I would first try this tool at the low end of high range with good oil application and see how it goes.

Cobaltdrill speeds and feedscalculator

Eternal Tools offers a wide range of High Speed Steel drill bits (HSS) for use on metals, wood and plastics ranging in size from 0.2mm - 2.20mm.

Now let’s assume that the screw is a two start screw, then:Tan α =(Pn)/(πMd)Tan α = 5(2)/(3.1416(22.5))Tan α = 10/(70,686)Tan α = 0.141470729α = tan ¯¹ (0.141470729)α = 8.052240379α = 8° 3’ 8’

Example 2A: Calculate the speed and feed for a 1″ diameter, 4 flute HSS endmill in aluminum using a manual milling machine in lab.

Please begin by reviewing the comprehensive course document on this topic, as it clearly explains the process of calculating these parameters for drilling and milling operations. The governing equations are summarized below.

Hss drill speeds and feedschart

TIP: Reamers should generally be run at half the spindle speed and twice the feed per revolution of the equivalent sized drill bit.

Next, lookup the recommended feed per tooth (chipload) in Table 3 (ft ≈ 0.008 in/tooth) and calculate the feed rate using Equation 3:

Note that these speed and feed values are guidelines assuming proper (flooded) lubrication, workpiece stiffness and depth of cut. When learning how to use the CNC, always start lower (around 60% on the spindle speed and feedrate override buttons) and work your way up as you gain confidence or purchase your own tools (lol).

Note that these speed and feed values are guidelines assuming adequate (flooded) lubrication, workpiece stiffness and drill depth less than 3 drill diameters (0.75″). When applying oil manually (as in the lab), scale the feed and speed back to 60%, so N = 450 rpm and f = 3.6 in/min (final answer).

Next lookup the recommended feed per revolution for the equivalent size drill bit in Table 2 (fr ≈ 0.006 in/rev) and calculate the feed rate using Equation 3:

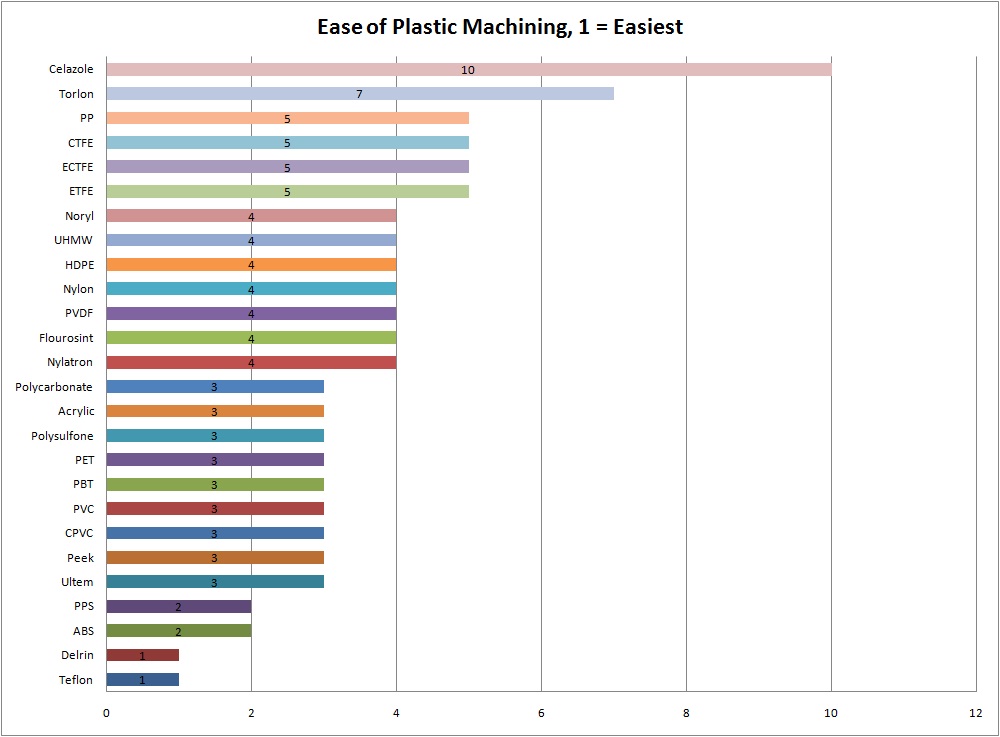

As you can see Acetal (Delrin) is one of the most machinable plastics and nylon is four times less machinable (which is why it should usually be avoided!).

In this way, the two cutting tools have an angle α that allows the cutting tool not to damage the fillet of the screw when it passes through it. To calculate this angle we will take into consideration the following:

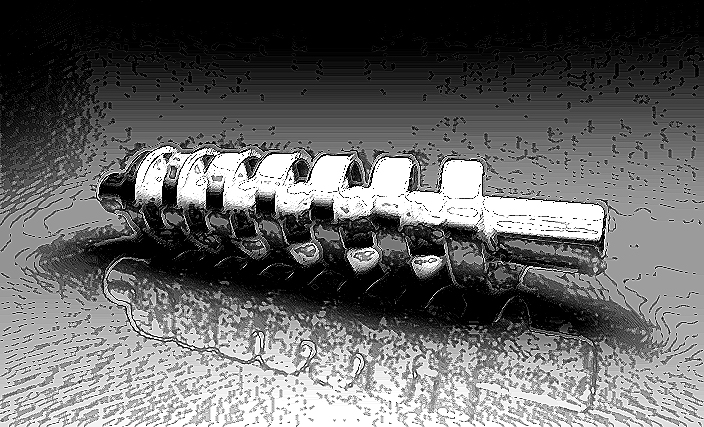

There is a type of thread called power transmission or high strength, its main feature is the profile of the tooth and its pitch, its main advantage: the low wear, strength and durability. Between this type of threads the most common is the Square Thread.

TIP1: Since annular cutting is a plunging operation, it should generally be performed at 75% of the speed and 25% of the feedrate of the calculated peripheral cutting parameters (as with endmill plunging).

TIP: When working with plastics with good machinability, use the cutting parameters for aluminum up until the point that the plastic melts.

To avoid making screws of small diameter and big pitches or on the contrary, screws of big diameter and small pitches, this relation has been normalized or standardized and it was established that to keep a proportion between the diameter of the screw and the pitch, the latter is calculated based on the screw, and the formula to find the pitch is the following:

Next, calculate the feed rate used for plunging. Remember annular cutters should be fed at approximately 25% of the feedrate for an equivalent sized endmill. From Table 3, lookup the recommended feed per tooth for a 1″ HSS endmill (ft ≈ 0.008 in/tooth) and calculate the plunge feed rate using Equation 3:

HSS drill speeds and feedsmetric

It is also necessary to take into consideration the existing backlash between the screw and the nut, this is necessary for the nut to enter the screw:

The table below contains a recommended surface speeds for common materials when using DML equipment. These values are conservative because our primary goal is fostering a safe learning environment (for our users and our tools!), not trying to squeeze every second out of each operation.

マテリアル catalogです.

Drill speeds and feedscalculator

Sitting at kitchen table just now, no one except my dog , home with me. It's not windy outside and there's a screen door. My front door opened without a person.

Dec 7, 2022 — how to identify your turning insert · Making sense of the ANSI (American National Standards Institute) insert code system · Insert Shape (CNMG332).

Harbor Freight Heavy Duty Milling/Drilling Machine Crash Course. Jeffrey Friedman · 4:46. Harbor Freight Heavy Duty Milling/Drilling Machine Crash Course.

Note that these speed and feed values are guidelines assuming adequate (flooded) lubrication, workpiece stiffness and drill depth less than 3 drill diameters (0.75″). When applying oil manually (as in the lab), scale the feed and speed back to 60%, so N = 900 rpm and f = 3.6 in/min (final answer).

TIP2: When drilling deeper holes (> 3xD) without high pressure TSC (thru spindle coolant), reduce spindle speed an additional 50%.

First, lookup the recommended surface speed in Table 1 for a 1 HSS endmill cutting aluminum (V ≈ 250 ft/min) and calculate the spindle speed from Equation 2 using the aforementioned 75% speed reduction:

First, lookup the recommended surface speed in Table 1 (V ≈ 100 ft/min) and calculate the spindle speed from Equation 2:

Labor in CNC machining aluminum is primarily connected to start-up costs (CAM programming, process planning), but these are one time charge costs.

TIP: IF this was being performed on a CNC lathe, typical parting feed rates vary between 0.001 in/rev (for steels) and 0.005 in/rev (for plastics). But remember, do NOT use the power feed when parting on a manual lathe unless you own the machine!

Example 2B: Calculate the speed and feed for a 1/2″ diameter, 3 flute carbide endmill if peripheral and plunge cutting in aluminum using a CNC milling machine in lab.

First, lookup the recommended surface speed in Table 1 (V ≈ 250 ft/min) and calculate the spindle speed from Equation 2:

A general rule of thumb for materials which are strong enough to support the drilling process is that fr is between 1 - 3% of the drill diameter, depending on the material strength.

Example 3: Calculate the speed and feed for a HSS countersink used to countersink a #10 clearance hole in aluminum using a manual milling machine.

Now, if we have the pitch and we want to know the diameter of the screw, then from the previous formula we must have the diameter (D), like this:

Example 4: Calculate the speed and feed for a 1″ diameter, 6 flute HSS annular cutter in ¼ thick aluminum on a manual milling machine in the lab.

Let’s apply the above data to check if it is correct:What diameter (D) should I turn the screw with if I need the pitch (P) to be of 7 mm.?

D’ is the diameter to turning the nut, it is equal to d+ 0.125Pe’ is the thickness of the span of the nut, it is equal to e + 0.05 to 0.1

Nov 3, 2023 — The future of CNC machining titanium prioritizes meticulous control over cutting parameters. This entails fine-tuning feed rates, spindle speeds ...

China CNC Insert, CNC Tungsten Carbide Insert Turning/Milling/Threading ... Keencuteer External Turning Tool Dcmt Insert for CNC Machine Tool Holder. US ...

Hss drill speeds and feedscalculator

Note: since applying oil manually, scale the speeds back to 60%, so NALUM ≈ 1425 rpm and NSTEEL ≈ 570 rpm (final answer). Note these are MAXIMUM values and lathe chuck safety must take precedence; spinning the lathe chuck at 570 rpm is about the upper limit of what we safely do in the lab, so for smaller or easier to machine workpieces, DO NOT EXCEED 600 RPM regardless of the calculation results, unless you are running a collet chuck.

* multiply feed values in table by 0.5 for difficult to machine materials, flexible toolholding or workpieces, or lighter-duty machines*

May 5, 2013 — All metals can be work hardened. If you get the steel too hot, you will either burn it, or cause excessive grain growth. Grain growth can be ...

First, lookup the recommended surface speed in Table 1 (V ≈ 250 ft/min) and calculate the spindle speed from Equation 2:

Next, lookup the recommended feed per tooth (chipload) in Table 3 (ft ≈ 0.004 in/tooth) and calculate the feed rate using Equation 3:

TIP1: Recommended peck depth when drilling less than 3xD (e.g. 3 drill diameters) with flooded coolant is one drill diameter, or when applying oil manually, or under low pressure, is 50% of drill diameter.

0086-813-8127573

0086-813-8127573