Solid Carbide Drill Bits for Stainless Steel - do you need special drill bits for metal

c. Output attachments to subfolders—The third parameter is an optional input to select a check box if the user wants to download the attachments to individual sub-folders based on a field value. Notice that the data type is Boolean. If checked (true), create sub-folders, otherwise load all files into a single output folder.

Types ofmillingcutters with diagram

A: Coating your tools makes them last a lot longer and less sticky to some types of workpieces. Therefore, milling bits with coatings are generally better. However, coatings also increase the cost of the tools, so your budget should also be a determining factor.

With a suite of data management geoprocessing tools to manage, maintain, and work with attachments, it is still possible to discover that the tool you need doesn’t currently exist. For example, there is not a Download Attachments tool. With a do-it-yourself (DIY) enthusiasm, I’ll show you how to create your own custom data management geoprocessing tool using ArcPy and ArcGIS Pro script tools. The tool will allow you to quickly download attachments and optionally rename them without manually accessing and saving one attachment at a time.

In terms of price, we offer a killer even for the best quality of jobs. Our prices are 30% lower than that of the average company and suit the budget of all kinds of startups.

A: It all depends on the type of project you’re working on. There are different types of processes and various types of tools to handle them.

h. Keep existing filename and add field value as a suffix to filename – This optional parameter adds selected field values with an underscore to the end of the original filename.

d. Subfolder names by field—The fourth parameter is dependent on the third parameter and will only display if the optional check box is checked. If it’s checked, the user can then select a field from the feature class for the sub-folder names. (The validation script implements this behavior on the tool, which will also be available for review in a copy of the final tool).

Millingmachinetoolsname

High-speed steel, a better and more durable material than carbon steel, loses its hardness at 600 degrees Celsius. Its high melting point is due to the addition of some alloying metals like chromium, tungsten, and molybdenum in its manufacture. Just as the name implies, it is suitable for higher miller speeds and can withstand higher operating temperatures. This means it can cut even harder materials like steel or aluminium.

In every sector of engineering, experience in the field is a very vital factor and shows the credibility of the company. That is exactly what we offer you when you bring your jobs to RapidDirect. With nearly two decades of manufacturing experience, our staff members are experts in all types of CNC machining operations.

Every new script tool contains a standard validation script. Update this script with Python code to control the behavior of the tool. I like to refer to this script as making your tool a smart tool. Like error handling, one can think of this behavior as another option to mitigate errors before a user clicks the Run button. Therefore, the first parameter on the tool can return an error message for non-enabled feature classes or if it does not have any attachments to download. You can also control other behaviors of the tool, such as only showing the parameter to select a field if the check box has been selected.

This mill has a pipe-shape and looks inverted in form. Machinists use hollow mills for creating shapes like full points and form radii due to the cutting edge of the mill, which you can find on the inner part of the mill.

Slabmillingcutter

Choosing the right cutter for your job could be such a task, especially when you have to use the tool either at high temperatures or cutting hard materials. Here are a few tips to consider before picking the right milling bit:

This is a more varied type of milling cutter. It has a flat head with replaceable carbide cutting edges. Due to the fact that these cutting edges are on the side of the milling cutter, you can only cut horizontally and not axially. Machinists use face mills to make flat sections on raw materials. One reason why they remain one of the best types of the milling cutter is due to their replaceable cutting inserts, which makes them last even longer and give a better quality of work over a long period. You can also easily replace the inserts instead of having to buy another tool.

Note: The intent of this sample script and tool is to show one of many ways users can automate data management in a geodatabase. This sample does make a few assumptions, and individual circumstances may require users to change the code to meet specific needs. For instance, a feature class can participate in one or more relationship classes, and this sample does not check for multiple relationship classes. It does allow users to select a feature and it will download just the attachments from one or more selected features, but it does not verify if each feature has attachments to export. It also does not support date fields, as date types present issues for renaming folders and files and date conversion to text was beyond the scope of this sample. The script and tool should work for most users as is, but unforeseen errors and issues may occur. Please feel free to alter, update, and improve the script and tool to meet individual and organizational needs.

Mike loves to enhance the customer experience when working with Esri software, and has many opportunities to continue this passion as a product engineer on the Geodatabase Team. Outside of his GIS profession, he loves to tinker with tech gadgets, beat on the drums, bake pies and brownies, tell and snicker at dad jokes, and enjoy quiet time in the country with family and friends.

Maintaining communication and technical support with our clients is vital at RapidDirect. We offer unrivaled technical support to every project we work on. We make communication with our clients super-easy by providing 24/7 communication through our emails, phone, or website.

Fly cutters are cheaper types of face mills. They consist of the main tool body, which can have one or two tool bits attached to it. The double tool bit fly cutter is also known as double-end fly cutters or fly bars. Machinists use them for making broad and shallow cuts on a workpiece.

Tip: You can add a parameter description by updating the metadata. This allows a user to mouse-over the left side of each parameter to see descriptive information, also known as a tool tip. Right click on the script tool and select Edit Metadata. Under the Syntax Section select the down arrow of the parameter to update it’s description in the Dialog Explanation text box. When finished, click Save on the Metadata Ribbon.

If you think that writing code is fun, you’ll probably also like creating your geoprocessing tool interface with a custom script tool inside of ArcGIS Pro.

This article will discuss the types of milling cutters, the types of materials used in making milling cutters, and the tips to consider when choosing cutters. If you like to know more about milling machine tools, then you should read this article to the end.

Flutes are the channels on a milling bit. The number of flutes determines the feed rate of a milling bit. However, a high number of flutes also means you’ll have a large milling bit, which leaves less space for metal bits cut off from the workpiece.

Facemillingcutter

2. In the new script properties window, on the General tab, give the tool a name and label. The label will be the name that shows up on the tool. The name and label can be the same, but the name cannot have spaces. Provide a brief description about the tool. When a user hovers the mouse over the question mark (?) icon at the top right of the tool, the software will show a text window with the description.

The type of material your CNC machine tools are made from will determine the type of manufacturing process you can use them for. Let’s look at a few types of materials and the types of jobs CNC machine tools made out of them can handle:

Learn how to use the features of the Download Attachments Sample tool to export feature class attachments to a designated folder with the option to rename the files.

Why wait for ages to get your quote when you can get it instantly with RapidDirect? Once you use our website quoting platform, the algorithm sends you back your quote within the next minute. Click the button below and have a try!

There are different milling cutters, with each having distinctive features and uses. Here is a educational video that introduces the CNC tools:

b. Output Folder—The second parameter is a required output to choose a folder to store the downloaded attachments or sub-folders with attachments if applicable.

The extremely high level of precision needed within the aerospace industry makes CNC machining a suitable manufacturing process for the sector.

In conclusion, I hope that this sample script and script tool provide some functionality that can be useful in your current or future workflows. I always learn something new from sample scripts and demonstrations that I can apply directly to a current project or later use. While this tool is all about downloading attachments from a feature class, you might find it to be more helpful for automating other workflows, better understanding of the Describe function or tool behavior. Either way, have fun and good luck creating your own data management geoprocessing tool to download attachments. Feel free to edit, update, improve or customize for your individual or organizational needs!

With your script finished and imported into your script tool, you can run the tool on a feature class that has attachments you want to download to a specified folder. Optionally, you can organize the download attachments into subfolders based on field values in a field name of your choice. In my case, I downloaded airport picture attachments to subfolders for each airport name.

This is the cheapest material used in the making of milling cutters. It contains 0.6 – 1.5% carbon, silicon, and manganese. The reason for its cheap price is because it is not a really durable material. Therefore, machinists use it only for low-speed operations like turning. If used for high-speed operations, the carbon steel will tend to degenerate faster as carbon steel has a melting point of 200 degrees Celsius. Due to its low melting point, it can only cut relatively soft materials like plastics or foam.

The following static code snippet gives you a glimpse of how you will check to make sure the selected feature class has been enabled for attachments using the arcpy Describe function. You will also use the Describe function to return the associated ATTACH table. This table stores your attachments in the DATA column as binary large objects (BLOB data). If the ATTACH table is empty, your tool will notify the user that the selected feature class has no attachments to download with an error message.

SideMillingCutter

Good news! This sample tool has been implemented as a fully supported tool in ArcGIS Pro 3.3. Learn more about the new Export Attachments tool in this blog.

a. Input Feature Class—The first parameter will allow the user to select a feature class. Note: This parameter’s data type is a feature layer, rather than a feature class. What’s the difference? Selecting Feature Layer allows you to pick data from the Contents pane of the active map or from a folder location. Another benefit of using Feature Layer is that it will only export attachments for selected features (if the selected feature has attachments). Having the data type set to Feature Class would only allow a user to select a feature class using the folder icon. You’ll set this parameter to be a required input.

Additionally, check out these other helpful resources when working with attachments, geodata, Python, and custom script tools:

End Mill Cutter

f. Select Fields – This parameter will only appear if the checkbox for the Rename Output Filenames Boolean value equals true (checked). The script allows up to five field selections for renaming the exported files. The script tool validation script prevents date field selections, as the date data type was causing errors with renaming the files. If you would like to use the values from a date field, create a new text field and copy the dates to the new text field. Be aware that special characters such as slashes (“/”) or colons and semicolons (“:”, “;”) will likely cause an operating system error when attempting to rename files or sub-folders. Consider replacing special characters with spaces, underscores or hyphens.

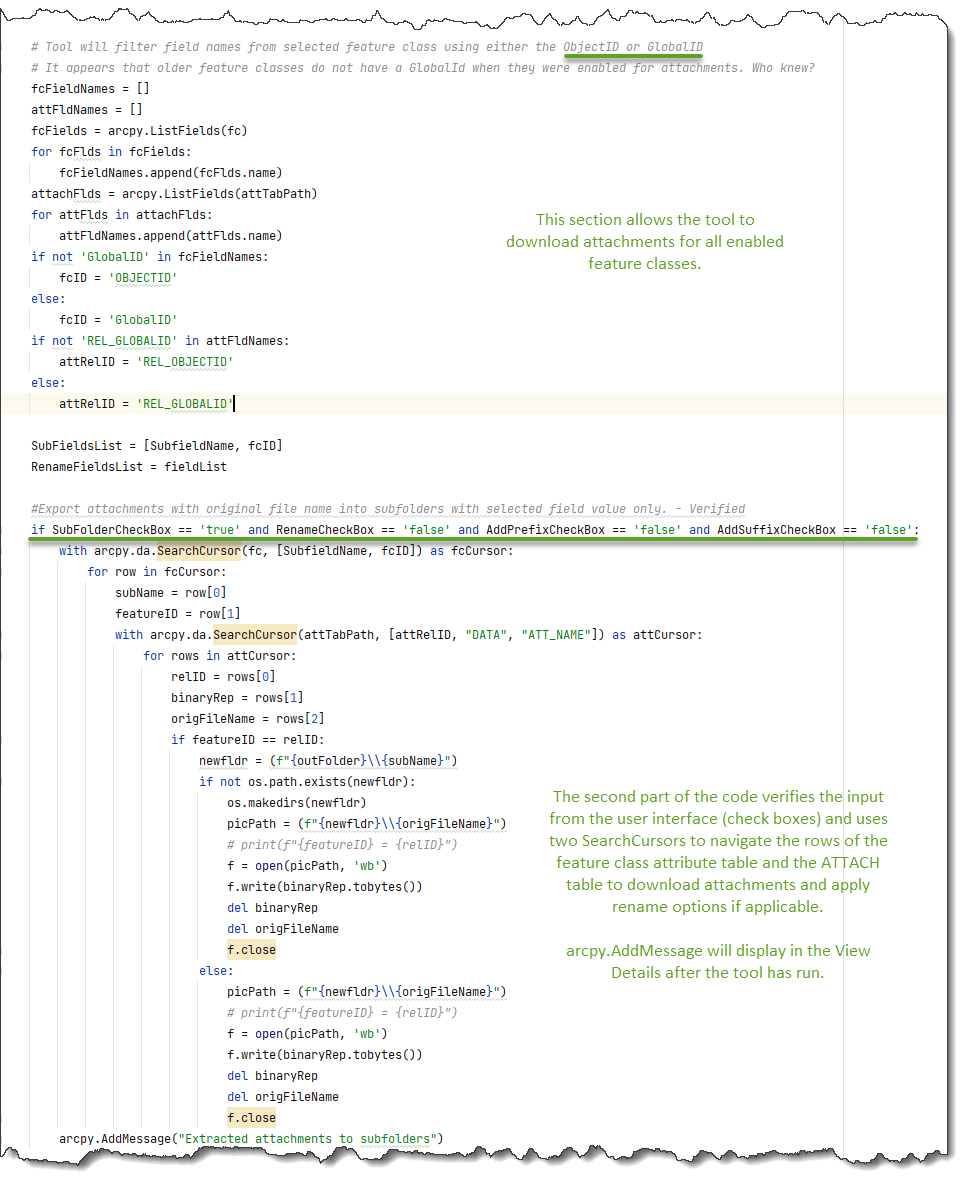

The second portion of the script verifies if the user wants to export the attachments to subfolders or rename them. Depending on the combination of options the end user chooses most of the code is similar within a series of elif statements. One important item to note. It is possible that a feature class that has been enabled for attachments may use either the OBJECTID with the REL_OBJECTID relationship in the ATTACH table, or GLOBALID’s for feature classes enabled in newer versions of the software. The script needs to check both so that all enabled feature classes work with the tool. This means that the tool should work with any enabled attachment feature class. Checkbox false on all options will download all attachments with their original names to the output folder only.

Notice that each parameter in the tool properties has a number on the left side, starting with zero. If you are thinking those are index numbers, you are correct. You will match each parameters index with updated variables in your script. The script will now use user input values instead of hard-coded values when the user clicks Run.

g. Keep existing filename and add field value as a prefix to filename – This optional parameter adds selected field values with an underscore to the beginning of the original filename.

The type of tool coating your CNC machining tool has also matters. Using coatings like titanium nitride improves the tool’s lifespan but also increases its cost. Also, some types of coatings make your tool less sticky, which means less lubricant use during work (further reducing the costs).

i. Output Folder Path—The last parameter is set to derived and hidden but is added if a user wants to use the new tool in ModelBuilder. The output path will appear as a result within the model.

Machinists use reamers to widen holes existing in the workpiece and give them a more precise finish and exact diameter due to their much tighter tolerance compared to other tools.

3. Click the Parameters tab in the Tool Properties window to create and add each tool parameter. This section is where you design the user interface of your tool. Users choose the feature class, and output folder as required parameters. Optionally, they can store the attachments in sub-folders in the output folder using field values. Field values can also be used to rename exported attachments.

End mills are one of the most popular types of milling cutters, and they are quite similar to drills due to their ability to cut materials axially. There are different variants of the CNC machine tool. They differ in the number of flutes and the different types of noses they have. Some could have up to eight flutes or more. The types of noses include:

With your script updated to gather the input from the user on the tools interface, you can save a copy of it and load the script into the tool.

However, your need might have to determine the type of tool to pick. If you need a tool that is really hard for just short-term work, you might be better off with the cemented ceramides or cutting ceramics.

In the hardness aspect, cutting ceramics is the strongest of all four materials. However, they also remain very susceptible to cracking and whipping when used on hard materials. Machinists use them to cut tough, strong materials like superalloys and cast iron. Although they are resistant to corrosion and heat, we wouldn’t recommend them to be used as machining tools as they tend to have a short tool life. However, due to their ability to withstand high heat operations, they can work on tools like superalloys, cast iron, or hard steels.

With your code completed and tested successfully, you can move on to designing your own script tool with a user-friendly interface to interact with the code. You can download a copy of the completed sample script later in this blog.

This type of mill cutter is not so common with modern machining centers. Machinists use them to mill flat surfaces as they have no side teeth. They have slab surfaces and are for general heavy-duty operations.

Here you will replace the hard-coded lines used for testing to now gather the feature class path, the output folder path, and the status of the checkboxes from what the user entered on the user interface of the tool.

MillingCutter Tool

Although this material is harder than high-speed steel, it is not as tough as high-speed steel. This means that although you can use them at higher operating temperatures without losing its hardness, it is more susceptible to cracking and chipping than high-speed steel. Due to their tendencies to crack, machinists mostly use them for high-quality surface finishes instead of cutting.

If you want to produce high-quality machined parts with a sleek appearance, it’s essential to consider some critical factors related to CNC machining.

Users will see this information as tool tips when they hover their mouse over the blue ‘i’ icon or required red asterisk at the left of each parameter.

While each of these categories has its function and uses, there’s no doubt that one of the most utilized types is the CNC cutting tools (CNC milling machine tools). Due to the fact that these milling cutters can change the tools on them automatically during the CNC machining process, they are one of the easiest to find in a machining workshop.

Millingcutter Diagram

Just as we have listed above, high-speed steel remains one of the best options of tools. It gives you the best of both worlds in terms of toughness and hardness.

To gather the information from what the user entered for each tool parameter, you will match the lines of code in the script with the parameter index on your new tool.

e. Rename Output Filenames – This is another optional parameter, and if checked, will allow the user to rename the exported images based on selected field values in the feature class attribute table. Note: Renamed files will have an underscore inserted between the field values. When renaming exported attachments based on field values the tool automatically appends the AttachmentID number as the last value to avoid duplicate filenames.

After years of teaching instructor-led classes and covering courses for geodatabases and Python automation, I was excited to recently join the geodatabase team to share new ways to assist our users with their workflows and projects. I know that students love examples, especially sample code and demonstrations when it comes to automating manual workflows with Python scripting.

Machinists use woodruff or keyseat cutters to cut key slots into parts, for example, shafts. The cutting tools have teeth perpendicular to the outside diameter to produce suitable slots for woodruff keys.

Choosing the right tool for a CNC machining job is extremely vital as it is an important factor which determines if the project turns out to be a success or not. Therefore, you need to be familiar with the right tool for every kind of job. A better alternative is to reach out to us at RapidDirect to handle all your CNC machining jobs. Here are a few reasons why you should reach out to us.

In addition, you’ll add the last parameter (hidden) to the end of the script to show an output result if a user chooses to use the tool in ModelBuilder (referencing index 8 on the tool).

You can easily identify ball cutters due to their hemispherical cutting tip, which the cutter employs in making corner radiuses on perpendicular faces.

The roughing end mills are usually the go-to CNC machine tool if you have to remove a large piece of material from the workpiece in a short period. In the place of speed, the cutter sacrifices precision and leaves a rough finish on the workpiece. The cut bit of metals it produces is always easy to clear due to their small size.

Machinists make gear cutters using a special type of milling machine known as a hobbing machine. The machine used to make the gear differs depending on the number of teeth of the gear you want to make.

There’s no doubt that there is no CNC machining without the CNC machining tools. We use these tools for a variety of operations, and they make the job easier and automated. They are different CNC machine tools, from the milling to the turning, drilling, or electrical discharge tools.

Geodatabases have supported the ability to enable feature classes (including stand-alone tables) to add attachments for many years. Attachments are one way to associate nongeographic data with geographic data. An example is attaching one or more pictures to a feature in a feature class. When enabled and attachments added, a user can mouse click on a feature to display a pop-up window showing its attributes and associated media data. GIS users have asked if it is possible to download attachments from an enabled feature class to a specified location along with options to rename the exported files.

Just as the name implies, this type of cutter has teeth both on the side and circumference. Machinists use this cutter to cut slots and grooves. Although they have a functional similarity to end mills, their use has decreased due to new technological advancements.

0086-813-8127573

0086-813-8127573