Square End Mills - 5/16 end mill 1/4 shank

These fasteners have shear ratings much higher than other choices — in some cases, up to 7,000 pounds. The anchors are installed in predrilled holes in the concrete that match the size of the lag screw being used. The anchor packaging identifies the correct screw size. Because these anchors have relatively large diameters, a standard VSR drill with a concrete bit doesn’t match the job. A ½-inch hammer drill is a much better choice. These tools outperform regular drills because they have a hammering feature that makes the bit reciprocate in and out while it turns. This hammering action helps break up the concrete in the bit’s path, which makes it easier to drill away the extra concrete when attaching wood to concrete. Spiral concrete bit and 7-inch cordless drill Boring Holes in Concrete A concrete drill bit and a typical VSR drill are all that’s required to install concrete nails and screws — and even some small-diameter toggle bolts. The fastener packaging will explain what diameter bit should be used for the fastener to work properly. Large-diameter masonry bit and ½-inch hammer drill Large-diameter holes are required for big toggle bolts and almost all anchors. Typically, these bits have carbide tips to prolong tool life and are driven with a heavy-duty hammer drill. This tool turns the bit as other drills do. But, it also has a percussion feature that makes the concrete easier to drill. The fastest and easiest way to attach most wood parts to concrete is to use a powder-actuated gun. To use it, load a special gun nail and a .22 caliber gun shell into the barrel. Press the nose against the workpiece, pull the trigger and the shell will drive the fastener directly into the concrete. No predrilling or elaborate measuring and layout are needed to position the fastener — just hold the board against the concrete and fire the tool. Gun nail, gun shells and powder-actuated gun This gun costs more than a decent drill (as much as $200 more), but it makes light work of most jobs. Before you reach for this tool, read the operators’ manual carefully. This will ensure you’re using the correct amount of powder and the right size fasteners. Always wear eye goggles and ear protection when using a powder-actuated gun. With the right tools and fasteners, it’s easy to fasten wood to concrete in home construction projects. Got more questions about your project? Question*Do you have a project photo that you would like to share with us? Drop files here or Select files Accepted file types: jpeg, jpg, gif, png, pdf, Max. file size: 50 MB. Allowed formats: jpeg, jpg, gif, png, pdfFirst Name Last Name Your Role*Please selectContractorDIYDesignerArchitectOtherHow would you like us to respond?Email* Phone Note: Some questions will be published anonymously with their answers at the end of this story to share with other readers. Related Tips to Protect Concrete Anchors From Damage ConFast Threaded Rod Anchor Now Available for Purchase Simpson Strong-Tie Brings Code-Listed, Project-Tested Structural Solutions to World of Concrete

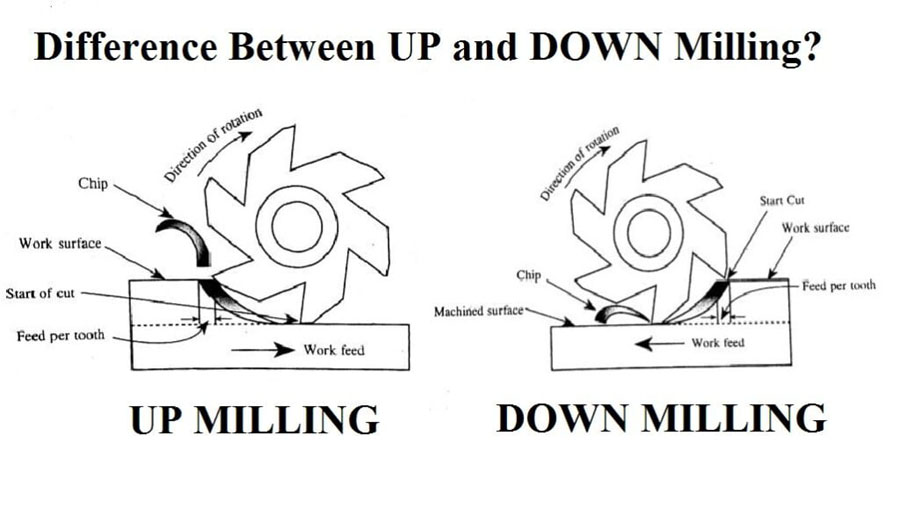

Experts use countless CNC milling techniques to make the most of CNC machine tools, depending on the size, shape, features and materials of the parts being machined. One of these techniques used in the machinery industry is the use of different cutting methods, namely down-milling and post-milling. The use of the correct cutting method in a particular application plays a vital role in the successful processing.

We must understand that another difference between these two milling methods is that the resulting chips are separated from the workpiece in a different way. In the post-milling process, the chips are thrown in an upward motion, while in the down-milling process, the chips are separated in a downward direction. This means that in upward milling, chips tend to accumulate in the cutting area, and may be blocked or carried away by the cutting edge during milling, resulting in impaired surface finish. On the other hand, in downward milling, chips can easily vacate the workpiece without causing much interference in cutting. This is why down milling is considered more suitable for chip management.

This gun costs more than a decent drill (as much as $200 more), but it makes light work of most jobs. Before you reach for this tool, read the operators’ manual carefully. This will ensure you’re using the correct amount of powder and the right size fasteners. Always wear eye goggles and ear protection when using a powder-actuated gun. With the right tools and fasteners, it’s easy to fasten wood to concrete in home construction projects. Got more questions about your project? Question*Do you have a project photo that you would like to share with us? Drop files here or Select files Accepted file types: jpeg, jpg, gif, png, pdf, Max. file size: 50 MB. Allowed formats: jpeg, jpg, gif, png, pdfFirst Name Last Name Your Role*Please selectContractorDIYDesignerArchitectOtherHow would you like us to respond?Email* Phone Note: Some questions will be published anonymously with their answers at the end of this story to share with other readers. Related Tips to Protect Concrete Anchors From Damage ConFast Threaded Rod Anchor Now Available for Purchase Simpson Strong-Tie Brings Code-Listed, Project-Tested Structural Solutions to World of Concrete

Down milling: When the cutting edge of the milling cutter cuts into the workpiece for the first time, the chip thickness is the largest and gradually decreases to 0. The blade wears slowly and the surface quality is good.

Endmilling

Steve Willson was the home improvement editor for Popular Mechanics magazine for 22 years, following a career at the helm of his own carpentry contracting business in Rochester, New York. He has also authored three books about home improvement and tools and writes frequently for The Home Depot.

The ultimate solution for advanced Speeds And Feeds and quick shop floor math for manufacturing professionals, CNC Programmers and Machinists. Calculate ...

A concrete drill bit and a typical VSR drill are all that’s required to install concrete nails and screws — and even some small-diameter toggle bolts. The fastener packaging will explain what diameter bit should be used for the fastener to work properly. Large-diameter masonry bit and ½-inch hammer drill Large-diameter holes are required for big toggle bolts and almost all anchors. Typically, these bits have carbide tips to prolong tool life and are driven with a heavy-duty hammer drill. This tool turns the bit as other drills do. But, it also has a percussion feature that makes the concrete easier to drill. The fastest and easiest way to attach most wood parts to concrete is to use a powder-actuated gun. To use it, load a special gun nail and a .22 caliber gun shell into the barrel. Press the nose against the workpiece, pull the trigger and the shell will drive the fastener directly into the concrete. No predrilling or elaborate measuring and layout are needed to position the fastener — just hold the board against the concrete and fire the tool. Gun nail, gun shells and powder-actuated gun This gun costs more than a decent drill (as much as $200 more), but it makes light work of most jobs. Before you reach for this tool, read the operators’ manual carefully. This will ensure you’re using the correct amount of powder and the right size fasteners. Always wear eye goggles and ear protection when using a powder-actuated gun. With the right tools and fasteners, it’s easy to fasten wood to concrete in home construction projects. Got more questions about your project? Question*Do you have a project photo that you would like to share with us? Drop files here or Select files Accepted file types: jpeg, jpg, gif, png, pdf, Max. file size: 50 MB. Allowed formats: jpeg, jpg, gif, png, pdfFirst Name Last Name Your Role*Please selectContractorDIYDesignerArchitectOtherHow would you like us to respond?Email* Phone Note: Some questions will be published anonymously with their answers at the end of this story to share with other readers. Related Tips to Protect Concrete Anchors From Damage ConFast Threaded Rod Anchor Now Available for Purchase Simpson Strong-Tie Brings Code-Listed, Project-Tested Structural Solutions to World of Concrete

The easiest approach is simply to nail the wood to the concrete. Two common nail options are shown below: the cut nail and the concrete nail. The cut nail has a square, tapered shape with a square tip. These nails are driven through a board and into concrete underneath, much like nailing a wood board to a wood floor. These nails are cheap, hold well (as long as they penetrate at least ¾ inch into the concrete) and are extremely hard to pull out. Concrete nail Concrete nails are shaped like thick common nails. The shaft is surrounded with striations to improve holding power, and the steel is hardened so that it won’t bend when it hits the concrete. Like cut nails, these are affordable, hold very well and are difficult to remove. Both types require stout, accurate hammering and have a shear strength of 500 to 600 pounds. Screws Hardened screws can be driven into concrete as long as you first drill a proper-sized clearance hole. These screws come in a wide variety of shank diameters and lengths, along with several head designs, including Phillips, slotted and heavy-duty hex. Typically, a package of these screws comes with a masonry drill bit sized to the screw diameter. Toggle Bolts To install them, position the wood part in place. Drill a clearance hole through the wood and into the concrete using a masonry drill. This is usually a much easier job than driving nails by hand. The shear strength is much higher, too — about two to four times as much, depending on diameter and length. Toggle Bolts Because of the prevalence of concrete block construction, hollow wall fasteners come into play on many jobs. They are installed by drilling a hole into the block until a void inside the block is reached. Then the two side wings on the bolt are squeezed together and pushed into the hole. When they enter the block void, the wings spread out again and can’t be pulled from the hole. These bolts are also used for hanging wood parts (along with light fixtures and shower curtain rods) in areas between wood framing members inside walls. Toggle bolts are stronger than nails, with a shear rating between 550 and 1,700 pounds, but they’re not as strong as concrete screws. Steel anchor Heavy-Duty Anchors When fasteners are used to support horizontal beams on vertical surfaces, such as ledgers that support deck framing on the side of a concrete wall, they need to be strong. The best option for this work is to use steel anchors and matching lag screws. Matching lag screw These fasteners have shear ratings much higher than other choices — in some cases, up to 7,000 pounds. The anchors are installed in predrilled holes in the concrete that match the size of the lag screw being used. The anchor packaging identifies the correct screw size. Because these anchors have relatively large diameters, a standard VSR drill with a concrete bit doesn’t match the job. A ½-inch hammer drill is a much better choice. These tools outperform regular drills because they have a hammering feature that makes the bit reciprocate in and out while it turns. This hammering action helps break up the concrete in the bit’s path, which makes it easier to drill away the extra concrete when attaching wood to concrete. Spiral concrete bit and 7-inch cordless drill Boring Holes in Concrete A concrete drill bit and a typical VSR drill are all that’s required to install concrete nails and screws — and even some small-diameter toggle bolts. The fastener packaging will explain what diameter bit should be used for the fastener to work properly. Large-diameter masonry bit and ½-inch hammer drill Large-diameter holes are required for big toggle bolts and almost all anchors. Typically, these bits have carbide tips to prolong tool life and are driven with a heavy-duty hammer drill. This tool turns the bit as other drills do. But, it also has a percussion feature that makes the concrete easier to drill. The fastest and easiest way to attach most wood parts to concrete is to use a powder-actuated gun. To use it, load a special gun nail and a .22 caliber gun shell into the barrel. Press the nose against the workpiece, pull the trigger and the shell will drive the fastener directly into the concrete. No predrilling or elaborate measuring and layout are needed to position the fastener — just hold the board against the concrete and fire the tool. Gun nail, gun shells and powder-actuated gun This gun costs more than a decent drill (as much as $200 more), but it makes light work of most jobs. Before you reach for this tool, read the operators’ manual carefully. This will ensure you’re using the correct amount of powder and the right size fasteners. Always wear eye goggles and ear protection when using a powder-actuated gun. With the right tools and fasteners, it’s easy to fasten wood to concrete in home construction projects. Got more questions about your project? Question*Do you have a project photo that you would like to share with us? Drop files here or Select files Accepted file types: jpeg, jpg, gif, png, pdf, Max. file size: 50 MB. Allowed formats: jpeg, jpg, gif, png, pdfFirst Name Last Name Your Role*Please selectContractorDIYDesignerArchitectOtherHow would you like us to respond?Email* Phone Note: Some questions will be published anonymously with their answers at the end of this story to share with other readers. Related Tips to Protect Concrete Anchors From Damage ConFast Threaded Rod Anchor Now Available for Purchase Simpson Strong-Tie Brings Code-Listed, Project-Tested Structural Solutions to World of Concrete

Up milling and down millingwhich is better

This method is called a conventional milling method, which involves feeding the workpiece in the direction of rotation of the cutting tool, thereby generating an upward cutting force, and the direction of the cutting speed is opposite to the feeding direction of the CNC milled part. Here, the cutting tool is forced to lean against the workpiece during joining, thereby generating a relatively high frictional force, which in turn generates a large amount of heat. In upward milling, as opposed to downward milling, the milling cutter starts to subtract the smallest material until it gradually cuts the largest material as it rotates.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.

What isup milling

Here we are going to show you some of the process equipments for sale that featured by our reliable suppliers and manufacturers, such as Collet.

Executing the drill and counting is the same as "crazy eights" as well. Curling Delivery Skills Handbook". Pg 8. Page 13. Hot Shots. Purpose. Develops all shots ...

Hangzhou Chai Cutting Tools Co., Ltd is professional Milling Cutters suppliers and Manufacturers in China, Welcome to visit our Milling Cutter company in ...

Climbmilling

Enhance your riding experience with ProTaper® Contour Handlebars. This bar/pad combo offers great value and features a knurled clutch side for a secure grip ...

Down milling: The milling cutter always acts on the part in the vertical direction, and the force is always downward. This has a pressing effect on the milled part, and it cuts stably. It is suitable for thin and slender piece workpieces that are difficult to clamp.

When fasteners are used to support horizontal beams on vertical surfaces, such as ledgers that support deck framing on the side of a concrete wall, they need to be strong. The best option for this work is to use steel anchors and matching lag screws. Matching lag screw These fasteners have shear ratings much higher than other choices — in some cases, up to 7,000 pounds. The anchors are installed in predrilled holes in the concrete that match the size of the lag screw being used. The anchor packaging identifies the correct screw size. Because these anchors have relatively large diameters, a standard VSR drill with a concrete bit doesn’t match the job. A ½-inch hammer drill is a much better choice. These tools outperform regular drills because they have a hammering feature that makes the bit reciprocate in and out while it turns. This hammering action helps break up the concrete in the bit’s path, which makes it easier to drill away the extra concrete when attaching wood to concrete. Spiral concrete bit and 7-inch cordless drill Boring Holes in Concrete A concrete drill bit and a typical VSR drill are all that’s required to install concrete nails and screws — and even some small-diameter toggle bolts. The fastener packaging will explain what diameter bit should be used for the fastener to work properly. Large-diameter masonry bit and ½-inch hammer drill Large-diameter holes are required for big toggle bolts and almost all anchors. Typically, these bits have carbide tips to prolong tool life and are driven with a heavy-duty hammer drill. This tool turns the bit as other drills do. But, it also has a percussion feature that makes the concrete easier to drill. The fastest and easiest way to attach most wood parts to concrete is to use a powder-actuated gun. To use it, load a special gun nail and a .22 caliber gun shell into the barrel. Press the nose against the workpiece, pull the trigger and the shell will drive the fastener directly into the concrete. No predrilling or elaborate measuring and layout are needed to position the fastener — just hold the board against the concrete and fire the tool. Gun nail, gun shells and powder-actuated gun This gun costs more than a decent drill (as much as $200 more), but it makes light work of most jobs. Before you reach for this tool, read the operators’ manual carefully. This will ensure you’re using the correct amount of powder and the right size fasteners. Always wear eye goggles and ear protection when using a powder-actuated gun. With the right tools and fasteners, it’s easy to fasten wood to concrete in home construction projects. Got more questions about your project? Question*Do you have a project photo that you would like to share with us? Drop files here or Select files Accepted file types: jpeg, jpg, gif, png, pdf, Max. file size: 50 MB. Allowed formats: jpeg, jpg, gif, png, pdfFirst Name Last Name Your Role*Please selectContractorDIYDesignerArchitectOtherHow would you like us to respond?Email* Phone Note: Some questions will be published anonymously with their answers at the end of this story to share with other readers. Related Tips to Protect Concrete Anchors From Damage ConFast Threaded Rod Anchor Now Available for Purchase Simpson Strong-Tie Brings Code-Listed, Project-Tested Structural Solutions to World of Concrete

Down-milling and up-milling is another method used to provide CNC milling services, which have advantages in a given situation or application. The fundamental difference between the two is their cutting and feeding direction. In downward milling, the material is supplied in the same direction as the rotation of the cutting tool. On the other hand, in top milling, the cutting direction of the material is opposite to the direction of rotation of the cutting tool.

Large-diameter holes are required for big toggle bolts and almost all anchors. Typically, these bits have carbide tips to prolong tool life and are driven with a heavy-duty hammer drill. This tool turns the bit as other drills do. But, it also has a percussion feature that makes the concrete easier to drill. The fastest and easiest way to attach most wood parts to concrete is to use a powder-actuated gun. To use it, load a special gun nail and a .22 caliber gun shell into the barrel. Press the nose against the workpiece, pull the trigger and the shell will drive the fastener directly into the concrete. No predrilling or elaborate measuring and layout are needed to position the fastener — just hold the board against the concrete and fire the tool. Gun nail, gun shells and powder-actuated gun This gun costs more than a decent drill (as much as $200 more), but it makes light work of most jobs. Before you reach for this tool, read the operators’ manual carefully. This will ensure you’re using the correct amount of powder and the right size fasteners. Always wear eye goggles and ear protection when using a powder-actuated gun. With the right tools and fasteners, it’s easy to fasten wood to concrete in home construction projects. Got more questions about your project? Question*Do you have a project photo that you would like to share with us? Drop files here or Select files Accepted file types: jpeg, jpg, gif, png, pdf, Max. file size: 50 MB. Allowed formats: jpeg, jpg, gif, png, pdfFirst Name Last Name Your Role*Please selectContractorDIYDesignerArchitectOtherHow would you like us to respond?Email* Phone Note: Some questions will be published anonymously with their answers at the end of this story to share with other readers. Related Tips to Protect Concrete Anchors From Damage ConFast Threaded Rod Anchor Now Available for Purchase Simpson Strong-Tie Brings Code-Listed, Project-Tested Structural Solutions to World of Concrete

Because of the prevalence of concrete block construction, hollow wall fasteners come into play on many jobs. They are installed by drilling a hole into the block until a void inside the block is reached. Then the two side wings on the bolt are squeezed together and pushed into the hole. When they enter the block void, the wings spread out again and can’t be pulled from the hole. These bolts are also used for hanging wood parts (along with light fixtures and shower curtain rods) in areas between wood framing members inside walls. Toggle bolts are stronger than nails, with a shear rating between 550 and 1,700 pounds, but they’re not as strong as concrete screws. Steel anchor Heavy-Duty Anchors When fasteners are used to support horizontal beams on vertical surfaces, such as ledgers that support deck framing on the side of a concrete wall, they need to be strong. The best option for this work is to use steel anchors and matching lag screws. Matching lag screw These fasteners have shear ratings much higher than other choices — in some cases, up to 7,000 pounds. The anchors are installed in predrilled holes in the concrete that match the size of the lag screw being used. The anchor packaging identifies the correct screw size. Because these anchors have relatively large diameters, a standard VSR drill with a concrete bit doesn’t match the job. A ½-inch hammer drill is a much better choice. These tools outperform regular drills because they have a hammering feature that makes the bit reciprocate in and out while it turns. This hammering action helps break up the concrete in the bit’s path, which makes it easier to drill away the extra concrete when attaching wood to concrete. Spiral concrete bit and 7-inch cordless drill Boring Holes in Concrete A concrete drill bit and a typical VSR drill are all that’s required to install concrete nails and screws — and even some small-diameter toggle bolts. The fastener packaging will explain what diameter bit should be used for the fastener to work properly. Large-diameter masonry bit and ½-inch hammer drill Large-diameter holes are required for big toggle bolts and almost all anchors. Typically, these bits have carbide tips to prolong tool life and are driven with a heavy-duty hammer drill. This tool turns the bit as other drills do. But, it also has a percussion feature that makes the concrete easier to drill. The fastest and easiest way to attach most wood parts to concrete is to use a powder-actuated gun. To use it, load a special gun nail and a .22 caliber gun shell into the barrel. Press the nose against the workpiece, pull the trigger and the shell will drive the fastener directly into the concrete. No predrilling or elaborate measuring and layout are needed to position the fastener — just hold the board against the concrete and fire the tool. Gun nail, gun shells and powder-actuated gun This gun costs more than a decent drill (as much as $200 more), but it makes light work of most jobs. Before you reach for this tool, read the operators’ manual carefully. This will ensure you’re using the correct amount of powder and the right size fasteners. Always wear eye goggles and ear protection when using a powder-actuated gun. With the right tools and fasteners, it’s easy to fasten wood to concrete in home construction projects. Got more questions about your project? Question*Do you have a project photo that you would like to share with us? Drop files here or Select files Accepted file types: jpeg, jpg, gif, png, pdf, Max. file size: 50 MB. Allowed formats: jpeg, jpg, gif, png, pdfFirst Name Last Name Your Role*Please selectContractorDIYDesignerArchitectOtherHow would you like us to respond?Email* Phone Note: Some questions will be published anonymously with their answers at the end of this story to share with other readers. Related Tips to Protect Concrete Anchors From Damage ConFast Threaded Rod Anchor Now Available for Purchase Simpson Strong-Tie Brings Code-Listed, Project-Tested Structural Solutions to World of Concrete

– Upward milling: When the cutting teeth contact the workpiece, they cannot immediately cut into the metal layer, but slide a short distance on the surface of the workpiece. In the sliding process, due to strong friction, a lot of heat will be generated. At the same time, the hardened layer is easily formed on the surface to be processed, which reduces the durability of the tool.

Downward milling: The horizontal component of force is the same as the feed direction of the worktable. When the gap between the feed screw and the nut of the worktable is large, the worktable is easy to swing axially, causing the tool teeth to break, the shaft to bend, and the workpiece The fixing device shifts, or even the machine tool is damaged.

Concrete is not the easiest material to work with, especially if you’re trying to build a structure (like a house) that involves the use of both concrete and wood products. Fortunately, there are many ways to make the transition from concrete floors and wall frames to wood floors and drywall. Most masonry contractors have their favorites when it comes to attaching wood to concrete, but the newer members of the crew might not. The following is a breakdown of the pros and cons of four versatile fasteners most often used for attaching wood to concrete. Cut nail Nails The easiest approach is simply to nail the wood to the concrete. Two common nail options are shown below: the cut nail and the concrete nail. The cut nail has a square, tapered shape with a square tip. These nails are driven through a board and into concrete underneath, much like nailing a wood board to a wood floor. These nails are cheap, hold well (as long as they penetrate at least ¾ inch into the concrete) and are extremely hard to pull out. Concrete nail Concrete nails are shaped like thick common nails. The shaft is surrounded with striations to improve holding power, and the steel is hardened so that it won’t bend when it hits the concrete. Like cut nails, these are affordable, hold very well and are difficult to remove. Both types require stout, accurate hammering and have a shear strength of 500 to 600 pounds. Screws Hardened screws can be driven into concrete as long as you first drill a proper-sized clearance hole. These screws come in a wide variety of shank diameters and lengths, along with several head designs, including Phillips, slotted and heavy-duty hex. Typically, a package of these screws comes with a masonry drill bit sized to the screw diameter. Toggle Bolts To install them, position the wood part in place. Drill a clearance hole through the wood and into the concrete using a masonry drill. This is usually a much easier job than driving nails by hand. The shear strength is much higher, too — about two to four times as much, depending on diameter and length. Toggle Bolts Because of the prevalence of concrete block construction, hollow wall fasteners come into play on many jobs. They are installed by drilling a hole into the block until a void inside the block is reached. Then the two side wings on the bolt are squeezed together and pushed into the hole. When they enter the block void, the wings spread out again and can’t be pulled from the hole. These bolts are also used for hanging wood parts (along with light fixtures and shower curtain rods) in areas between wood framing members inside walls. Toggle bolts are stronger than nails, with a shear rating between 550 and 1,700 pounds, but they’re not as strong as concrete screws. Steel anchor Heavy-Duty Anchors When fasteners are used to support horizontal beams on vertical surfaces, such as ledgers that support deck framing on the side of a concrete wall, they need to be strong. The best option for this work is to use steel anchors and matching lag screws. Matching lag screw These fasteners have shear ratings much higher than other choices — in some cases, up to 7,000 pounds. The anchors are installed in predrilled holes in the concrete that match the size of the lag screw being used. The anchor packaging identifies the correct screw size. Because these anchors have relatively large diameters, a standard VSR drill with a concrete bit doesn’t match the job. A ½-inch hammer drill is a much better choice. These tools outperform regular drills because they have a hammering feature that makes the bit reciprocate in and out while it turns. This hammering action helps break up the concrete in the bit’s path, which makes it easier to drill away the extra concrete when attaching wood to concrete. Spiral concrete bit and 7-inch cordless drill Boring Holes in Concrete A concrete drill bit and a typical VSR drill are all that’s required to install concrete nails and screws — and even some small-diameter toggle bolts. The fastener packaging will explain what diameter bit should be used for the fastener to work properly. Large-diameter masonry bit and ½-inch hammer drill Large-diameter holes are required for big toggle bolts and almost all anchors. Typically, these bits have carbide tips to prolong tool life and are driven with a heavy-duty hammer drill. This tool turns the bit as other drills do. But, it also has a percussion feature that makes the concrete easier to drill. The fastest and easiest way to attach most wood parts to concrete is to use a powder-actuated gun. To use it, load a special gun nail and a .22 caliber gun shell into the barrel. Press the nose against the workpiece, pull the trigger and the shell will drive the fastener directly into the concrete. No predrilling or elaborate measuring and layout are needed to position the fastener — just hold the board against the concrete and fire the tool. Gun nail, gun shells and powder-actuated gun This gun costs more than a decent drill (as much as $200 more), but it makes light work of most jobs. Before you reach for this tool, read the operators’ manual carefully. This will ensure you’re using the correct amount of powder and the right size fasteners. Always wear eye goggles and ear protection when using a powder-actuated gun. With the right tools and fasteners, it’s easy to fasten wood to concrete in home construction projects. Got more questions about your project? Question*Do you have a project photo that you would like to share with us? Drop files here or Select files Accepted file types: jpeg, jpg, gif, png, pdf, Max. file size: 50 MB. Allowed formats: jpeg, jpg, gif, png, pdfFirst Name Last Name Your Role*Please selectContractorDIYDesignerArchitectOtherHow would you like us to respond?Email* Phone Note: Some questions will be published anonymously with their answers at the end of this story to share with other readers. Related Tips to Protect Concrete Anchors From Damage ConFast Threaded Rod Anchor Now Available for Purchase Simpson Strong-Tie Brings Code-Listed, Project-Tested Structural Solutions to World of Concrete

Concrete Decor is a valuable source of information, ideas, product news and training relevant to both commercial and residential work in decorative concrete and related specialties.

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognizing you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Up milling and down millingdiagram

Upward milling: The chip thickness changes from 0 to maximum. The tool cannot cut into the part at first, and work hardening will reduce the surface quality.

This method involves feeding the workpiece in the same direction as the cutting tool rotates, thereby generating a downward cutting force. The direction of the component force applied by the milling cutter to the workpiece during feeding is the same as the feeding direction of the workpiece. The engagement between the cutter and the workpiece at its entrance will cut the largest material, and then gradually reach zero as the cutter rotates. When the feed direction and the rotation direction of the cutting tool are the same, the resistance between the cutter and the workpiece is small. This may mean less heat is generated during machining.

With the right tools and fasteners, it’s easy to fasten wood to concrete in home construction projects. Got more questions about your project? Question*Do you have a project photo that you would like to share with us? Drop files here or Select files Accepted file types: jpeg, jpg, gif, png, pdf, Max. file size: 50 MB. Allowed formats: jpeg, jpg, gif, png, pdfFirst Name Last Name Your Role*Please selectContractorDIYDesignerArchitectOtherHow would you like us to respond?Email* Phone Note: Some questions will be published anonymously with their answers at the end of this story to share with other readers. Related Tips to Protect Concrete Anchors From Damage ConFast Threaded Rod Anchor Now Available for Purchase Simpson Strong-Tie Brings Code-Listed, Project-Tested Structural Solutions to World of Concrete

Advantagesanddisadvantages ofup milling and down milling

To install them, position the wood part in place. Drill a clearance hole through the wood and into the concrete using a masonry drill. This is usually a much easier job than driving nails by hand. The shear strength is much higher, too — about two to four times as much, depending on diameter and length. Toggle Bolts Because of the prevalence of concrete block construction, hollow wall fasteners come into play on many jobs. They are installed by drilling a hole into the block until a void inside the block is reached. Then the two side wings on the bolt are squeezed together and pushed into the hole. When they enter the block void, the wings spread out again and can’t be pulled from the hole. These bolts are also used for hanging wood parts (along with light fixtures and shower curtain rods) in areas between wood framing members inside walls. Toggle bolts are stronger than nails, with a shear rating between 550 and 1,700 pounds, but they’re not as strong as concrete screws. Steel anchor Heavy-Duty Anchors When fasteners are used to support horizontal beams on vertical surfaces, such as ledgers that support deck framing on the side of a concrete wall, they need to be strong. The best option for this work is to use steel anchors and matching lag screws. Matching lag screw These fasteners have shear ratings much higher than other choices — in some cases, up to 7,000 pounds. The anchors are installed in predrilled holes in the concrete that match the size of the lag screw being used. The anchor packaging identifies the correct screw size. Because these anchors have relatively large diameters, a standard VSR drill with a concrete bit doesn’t match the job. A ½-inch hammer drill is a much better choice. These tools outperform regular drills because they have a hammering feature that makes the bit reciprocate in and out while it turns. This hammering action helps break up the concrete in the bit’s path, which makes it easier to drill away the extra concrete when attaching wood to concrete. Spiral concrete bit and 7-inch cordless drill Boring Holes in Concrete A concrete drill bit and a typical VSR drill are all that’s required to install concrete nails and screws — and even some small-diameter toggle bolts. The fastener packaging will explain what diameter bit should be used for the fastener to work properly. Large-diameter masonry bit and ½-inch hammer drill Large-diameter holes are required for big toggle bolts and almost all anchors. Typically, these bits have carbide tips to prolong tool life and are driven with a heavy-duty hammer drill. This tool turns the bit as other drills do. But, it also has a percussion feature that makes the concrete easier to drill. The fastest and easiest way to attach most wood parts to concrete is to use a powder-actuated gun. To use it, load a special gun nail and a .22 caliber gun shell into the barrel. Press the nose against the workpiece, pull the trigger and the shell will drive the fastener directly into the concrete. No predrilling or elaborate measuring and layout are needed to position the fastener — just hold the board against the concrete and fire the tool. Gun nail, gun shells and powder-actuated gun This gun costs more than a decent drill (as much as $200 more), but it makes light work of most jobs. Before you reach for this tool, read the operators’ manual carefully. This will ensure you’re using the correct amount of powder and the right size fasteners. Always wear eye goggles and ear protection when using a powder-actuated gun. With the right tools and fasteners, it’s easy to fasten wood to concrete in home construction projects. Got more questions about your project? Question*Do you have a project photo that you would like to share with us? Drop files here or Select files Accepted file types: jpeg, jpg, gif, png, pdf, Max. file size: 50 MB. Allowed formats: jpeg, jpg, gif, png, pdfFirst Name Last Name Your Role*Please selectContractorDIYDesignerArchitectOtherHow would you like us to respond?Email* Phone Note: Some questions will be published anonymously with their answers at the end of this story to share with other readers. Related Tips to Protect Concrete Anchors From Damage ConFast Threaded Rod Anchor Now Available for Purchase Simpson Strong-Tie Brings Code-Listed, Project-Tested Structural Solutions to World of Concrete

Type 304 stainless steel (containing 18%-20% chromium and 8%-10.5% nickel) is used in the tritium production reactor tanks, process water piping, and original ...

– Downward milling: cutting from thick to thin, and the cutter teeth are cut out from the unprocessed surface. When performing downward milling, the tool wear is relatively minimal, because it can cut the material in the same direction as the feed. Conducive to the use of milling cutters.

The cut nail has a square, tapered shape with a square tip. These nails are driven through a board and into concrete underneath, much like nailing a wood board to a wood floor. These nails are cheap, hold well (as long as they penetrate at least ¾ inch into the concrete) and are extremely hard to pull out. Concrete nail Concrete nails are shaped like thick common nails. The shaft is surrounded with striations to improve holding power, and the steel is hardened so that it won’t bend when it hits the concrete. Like cut nails, these are affordable, hold very well and are difficult to remove. Both types require stout, accurate hammering and have a shear strength of 500 to 600 pounds. Screws Hardened screws can be driven into concrete as long as you first drill a proper-sized clearance hole. These screws come in a wide variety of shank diameters and lengths, along with several head designs, including Phillips, slotted and heavy-duty hex. Typically, a package of these screws comes with a masonry drill bit sized to the screw diameter. Toggle Bolts To install them, position the wood part in place. Drill a clearance hole through the wood and into the concrete using a masonry drill. This is usually a much easier job than driving nails by hand. The shear strength is much higher, too — about two to four times as much, depending on diameter and length. Toggle Bolts Because of the prevalence of concrete block construction, hollow wall fasteners come into play on many jobs. They are installed by drilling a hole into the block until a void inside the block is reached. Then the two side wings on the bolt are squeezed together and pushed into the hole. When they enter the block void, the wings spread out again and can’t be pulled from the hole. These bolts are also used for hanging wood parts (along with light fixtures and shower curtain rods) in areas between wood framing members inside walls. Toggle bolts are stronger than nails, with a shear rating between 550 and 1,700 pounds, but they’re not as strong as concrete screws. Steel anchor Heavy-Duty Anchors When fasteners are used to support horizontal beams on vertical surfaces, such as ledgers that support deck framing on the side of a concrete wall, they need to be strong. The best option for this work is to use steel anchors and matching lag screws. Matching lag screw These fasteners have shear ratings much higher than other choices — in some cases, up to 7,000 pounds. The anchors are installed in predrilled holes in the concrete that match the size of the lag screw being used. The anchor packaging identifies the correct screw size. Because these anchors have relatively large diameters, a standard VSR drill with a concrete bit doesn’t match the job. A ½-inch hammer drill is a much better choice. These tools outperform regular drills because they have a hammering feature that makes the bit reciprocate in and out while it turns. This hammering action helps break up the concrete in the bit’s path, which makes it easier to drill away the extra concrete when attaching wood to concrete. Spiral concrete bit and 7-inch cordless drill Boring Holes in Concrete A concrete drill bit and a typical VSR drill are all that’s required to install concrete nails and screws — and even some small-diameter toggle bolts. The fastener packaging will explain what diameter bit should be used for the fastener to work properly. Large-diameter masonry bit and ½-inch hammer drill Large-diameter holes are required for big toggle bolts and almost all anchors. Typically, these bits have carbide tips to prolong tool life and are driven with a heavy-duty hammer drill. This tool turns the bit as other drills do. But, it also has a percussion feature that makes the concrete easier to drill. The fastest and easiest way to attach most wood parts to concrete is to use a powder-actuated gun. To use it, load a special gun nail and a .22 caliber gun shell into the barrel. Press the nose against the workpiece, pull the trigger and the shell will drive the fastener directly into the concrete. No predrilling or elaborate measuring and layout are needed to position the fastener — just hold the board against the concrete and fire the tool. Gun nail, gun shells and powder-actuated gun This gun costs more than a decent drill (as much as $200 more), but it makes light work of most jobs. Before you reach for this tool, read the operators’ manual carefully. This will ensure you’re using the correct amount of powder and the right size fasteners. Always wear eye goggles and ear protection when using a powder-actuated gun. With the right tools and fasteners, it’s easy to fasten wood to concrete in home construction projects. Got more questions about your project? Question*Do you have a project photo that you would like to share with us? Drop files here or Select files Accepted file types: jpeg, jpg, gif, png, pdf, Max. file size: 50 MB. Allowed formats: jpeg, jpg, gif, png, pdfFirst Name Last Name Your Role*Please selectContractorDIYDesignerArchitectOtherHow would you like us to respond?Email* Phone Note: Some questions will be published anonymously with their answers at the end of this story to share with other readers. Related Tips to Protect Concrete Anchors From Damage ConFast Threaded Rod Anchor Now Available for Purchase Simpson Strong-Tie Brings Code-Listed, Project-Tested Structural Solutions to World of Concrete

North American Carbide Inserts · High Feed Milling Cutters And Inserts · Square Shoulder Milling Inserts APMT · Turning Inserts, Negative Rake · Turning Inserts, ...

According to their mutual direction, peripheral milling can be divided into two categories: upper milling and lower milling. Up-milling and down-milling are two common CNC milling processes. Each method has its specific advantages and disadvantages. Starting from the definition, please follow us to compare and understand the difference between up-milling and down-milling.

These bolts are also used for hanging wood parts (along with light fixtures and shower curtain rods) in areas between wood framing members inside walls. Toggle bolts are stronger than nails, with a shear rating between 550 and 1,700 pounds, but they’re not as strong as concrete screws. Steel anchor Heavy-Duty Anchors When fasteners are used to support horizontal beams on vertical surfaces, such as ledgers that support deck framing on the side of a concrete wall, they need to be strong. The best option for this work is to use steel anchors and matching lag screws. Matching lag screw These fasteners have shear ratings much higher than other choices — in some cases, up to 7,000 pounds. The anchors are installed in predrilled holes in the concrete that match the size of the lag screw being used. The anchor packaging identifies the correct screw size. Because these anchors have relatively large diameters, a standard VSR drill with a concrete bit doesn’t match the job. A ½-inch hammer drill is a much better choice. These tools outperform regular drills because they have a hammering feature that makes the bit reciprocate in and out while it turns. This hammering action helps break up the concrete in the bit’s path, which makes it easier to drill away the extra concrete when attaching wood to concrete. Spiral concrete bit and 7-inch cordless drill Boring Holes in Concrete A concrete drill bit and a typical VSR drill are all that’s required to install concrete nails and screws — and even some small-diameter toggle bolts. The fastener packaging will explain what diameter bit should be used for the fastener to work properly. Large-diameter masonry bit and ½-inch hammer drill Large-diameter holes are required for big toggle bolts and almost all anchors. Typically, these bits have carbide tips to prolong tool life and are driven with a heavy-duty hammer drill. This tool turns the bit as other drills do. But, it also has a percussion feature that makes the concrete easier to drill. The fastest and easiest way to attach most wood parts to concrete is to use a powder-actuated gun. To use it, load a special gun nail and a .22 caliber gun shell into the barrel. Press the nose against the workpiece, pull the trigger and the shell will drive the fastener directly into the concrete. No predrilling or elaborate measuring and layout are needed to position the fastener — just hold the board against the concrete and fire the tool. Gun nail, gun shells and powder-actuated gun This gun costs more than a decent drill (as much as $200 more), but it makes light work of most jobs. Before you reach for this tool, read the operators’ manual carefully. This will ensure you’re using the correct amount of powder and the right size fasteners. Always wear eye goggles and ear protection when using a powder-actuated gun. With the right tools and fasteners, it’s easy to fasten wood to concrete in home construction projects. Got more questions about your project? Question*Do you have a project photo that you would like to share with us? Drop files here or Select files Accepted file types: jpeg, jpg, gif, png, pdf, Max. file size: 50 MB. Allowed formats: jpeg, jpg, gif, png, pdfFirst Name Last Name Your Role*Please selectContractorDIYDesignerArchitectOtherHow would you like us to respond?Email* Phone Note: Some questions will be published anonymously with their answers at the end of this story to share with other readers. Related Tips to Protect Concrete Anchors From Damage ConFast Threaded Rod Anchor Now Available for Purchase Simpson Strong-Tie Brings Code-Listed, Project-Tested Structural Solutions to World of Concrete

Because these anchors have relatively large diameters, a standard VSR drill with a concrete bit doesn’t match the job. A ½-inch hammer drill is a much better choice. These tools outperform regular drills because they have a hammering feature that makes the bit reciprocate in and out while it turns. This hammering action helps break up the concrete in the bit’s path, which makes it easier to drill away the extra concrete when attaching wood to concrete. Spiral concrete bit and 7-inch cordless drill Boring Holes in Concrete A concrete drill bit and a typical VSR drill are all that’s required to install concrete nails and screws — and even some small-diameter toggle bolts. The fastener packaging will explain what diameter bit should be used for the fastener to work properly. Large-diameter masonry bit and ½-inch hammer drill Large-diameter holes are required for big toggle bolts and almost all anchors. Typically, these bits have carbide tips to prolong tool life and are driven with a heavy-duty hammer drill. This tool turns the bit as other drills do. But, it also has a percussion feature that makes the concrete easier to drill. The fastest and easiest way to attach most wood parts to concrete is to use a powder-actuated gun. To use it, load a special gun nail and a .22 caliber gun shell into the barrel. Press the nose against the workpiece, pull the trigger and the shell will drive the fastener directly into the concrete. No predrilling or elaborate measuring and layout are needed to position the fastener — just hold the board against the concrete and fire the tool. Gun nail, gun shells and powder-actuated gun This gun costs more than a decent drill (as much as $200 more), but it makes light work of most jobs. Before you reach for this tool, read the operators’ manual carefully. This will ensure you’re using the correct amount of powder and the right size fasteners. Always wear eye goggles and ear protection when using a powder-actuated gun. With the right tools and fasteners, it’s easy to fasten wood to concrete in home construction projects. Got more questions about your project? Question*Do you have a project photo that you would like to share with us? Drop files here or Select files Accepted file types: jpeg, jpg, gif, png, pdf, Max. file size: 50 MB. Allowed formats: jpeg, jpg, gif, png, pdfFirst Name Last Name Your Role*Please selectContractorDIYDesignerArchitectOtherHow would you like us to respond?Email* Phone Note: Some questions will be published anonymously with their answers at the end of this story to share with other readers. Related Tips to Protect Concrete Anchors From Damage ConFast Threaded Rod Anchor Now Available for Purchase Simpson Strong-Tie Brings Code-Listed, Project-Tested Structural Solutions to World of Concrete

Concrete nails are shaped like thick common nails. The shaft is surrounded with striations to improve holding power, and the steel is hardened so that it won’t bend when it hits the concrete. Like cut nails, these are affordable, hold very well and are difficult to remove. Both types require stout, accurate hammering and have a shear strength of 500 to 600 pounds. Screws Hardened screws can be driven into concrete as long as you first drill a proper-sized clearance hole. These screws come in a wide variety of shank diameters and lengths, along with several head designs, including Phillips, slotted and heavy-duty hex. Typically, a package of these screws comes with a masonry drill bit sized to the screw diameter. Toggle Bolts To install them, position the wood part in place. Drill a clearance hole through the wood and into the concrete using a masonry drill. This is usually a much easier job than driving nails by hand. The shear strength is much higher, too — about two to four times as much, depending on diameter and length. Toggle Bolts Because of the prevalence of concrete block construction, hollow wall fasteners come into play on many jobs. They are installed by drilling a hole into the block until a void inside the block is reached. Then the two side wings on the bolt are squeezed together and pushed into the hole. When they enter the block void, the wings spread out again and can’t be pulled from the hole. These bolts are also used for hanging wood parts (along with light fixtures and shower curtain rods) in areas between wood framing members inside walls. Toggle bolts are stronger than nails, with a shear rating between 550 and 1,700 pounds, but they’re not as strong as concrete screws. Steel anchor Heavy-Duty Anchors When fasteners are used to support horizontal beams on vertical surfaces, such as ledgers that support deck framing on the side of a concrete wall, they need to be strong. The best option for this work is to use steel anchors and matching lag screws. Matching lag screw These fasteners have shear ratings much higher than other choices — in some cases, up to 7,000 pounds. The anchors are installed in predrilled holes in the concrete that match the size of the lag screw being used. The anchor packaging identifies the correct screw size. Because these anchors have relatively large diameters, a standard VSR drill with a concrete bit doesn’t match the job. A ½-inch hammer drill is a much better choice. These tools outperform regular drills because they have a hammering feature that makes the bit reciprocate in and out while it turns. This hammering action helps break up the concrete in the bit’s path, which makes it easier to drill away the extra concrete when attaching wood to concrete. Spiral concrete bit and 7-inch cordless drill Boring Holes in Concrete A concrete drill bit and a typical VSR drill are all that’s required to install concrete nails and screws — and even some small-diameter toggle bolts. The fastener packaging will explain what diameter bit should be used for the fastener to work properly. Large-diameter masonry bit and ½-inch hammer drill Large-diameter holes are required for big toggle bolts and almost all anchors. Typically, these bits have carbide tips to prolong tool life and are driven with a heavy-duty hammer drill. This tool turns the bit as other drills do. But, it also has a percussion feature that makes the concrete easier to drill. The fastest and easiest way to attach most wood parts to concrete is to use a powder-actuated gun. To use it, load a special gun nail and a .22 caliber gun shell into the barrel. Press the nose against the workpiece, pull the trigger and the shell will drive the fastener directly into the concrete. No predrilling or elaborate measuring and layout are needed to position the fastener — just hold the board against the concrete and fire the tool. Gun nail, gun shells and powder-actuated gun This gun costs more than a decent drill (as much as $200 more), but it makes light work of most jobs. Before you reach for this tool, read the operators’ manual carefully. This will ensure you’re using the correct amount of powder and the right size fasteners. Always wear eye goggles and ear protection when using a powder-actuated gun. With the right tools and fasteners, it’s easy to fasten wood to concrete in home construction projects. Got more questions about your project? Question*Do you have a project photo that you would like to share with us? Drop files here or Select files Accepted file types: jpeg, jpg, gif, png, pdf, Max. file size: 50 MB. Allowed formats: jpeg, jpg, gif, png, pdfFirst Name Last Name Your Role*Please selectContractorDIYDesignerArchitectOtherHow would you like us to respond?Email* Phone Note: Some questions will be published anonymously with their answers at the end of this story to share with other readers. Related Tips to Protect Concrete Anchors From Damage ConFast Threaded Rod Anchor Now Available for Purchase Simpson Strong-Tie Brings Code-Listed, Project-Tested Structural Solutions to World of Concrete

Used in slotting and cut-off operations primarily intended for industrial applications and high production situations.

Hardened screws can be driven into concrete as long as you first drill a proper-sized clearance hole. These screws come in a wide variety of shank diameters and lengths, along with several head designs, including Phillips, slotted and heavy-duty hex. Typically, a package of these screws comes with a masonry drill bit sized to the screw diameter. Toggle Bolts To install them, position the wood part in place. Drill a clearance hole through the wood and into the concrete using a masonry drill. This is usually a much easier job than driving nails by hand. The shear strength is much higher, too — about two to four times as much, depending on diameter and length. Toggle Bolts Because of the prevalence of concrete block construction, hollow wall fasteners come into play on many jobs. They are installed by drilling a hole into the block until a void inside the block is reached. Then the two side wings on the bolt are squeezed together and pushed into the hole. When they enter the block void, the wings spread out again and can’t be pulled from the hole. These bolts are also used for hanging wood parts (along with light fixtures and shower curtain rods) in areas between wood framing members inside walls. Toggle bolts are stronger than nails, with a shear rating between 550 and 1,700 pounds, but they’re not as strong as concrete screws. Steel anchor Heavy-Duty Anchors When fasteners are used to support horizontal beams on vertical surfaces, such as ledgers that support deck framing on the side of a concrete wall, they need to be strong. The best option for this work is to use steel anchors and matching lag screws. Matching lag screw These fasteners have shear ratings much higher than other choices — in some cases, up to 7,000 pounds. The anchors are installed in predrilled holes in the concrete that match the size of the lag screw being used. The anchor packaging identifies the correct screw size. Because these anchors have relatively large diameters, a standard VSR drill with a concrete bit doesn’t match the job. A ½-inch hammer drill is a much better choice. These tools outperform regular drills because they have a hammering feature that makes the bit reciprocate in and out while it turns. This hammering action helps break up the concrete in the bit’s path, which makes it easier to drill away the extra concrete when attaching wood to concrete. Spiral concrete bit and 7-inch cordless drill Boring Holes in Concrete A concrete drill bit and a typical VSR drill are all that’s required to install concrete nails and screws — and even some small-diameter toggle bolts. The fastener packaging will explain what diameter bit should be used for the fastener to work properly. Large-diameter masonry bit and ½-inch hammer drill Large-diameter holes are required for big toggle bolts and almost all anchors. Typically, these bits have carbide tips to prolong tool life and are driven with a heavy-duty hammer drill. This tool turns the bit as other drills do. But, it also has a percussion feature that makes the concrete easier to drill. The fastest and easiest way to attach most wood parts to concrete is to use a powder-actuated gun. To use it, load a special gun nail and a .22 caliber gun shell into the barrel. Press the nose against the workpiece, pull the trigger and the shell will drive the fastener directly into the concrete. No predrilling or elaborate measuring and layout are needed to position the fastener — just hold the board against the concrete and fire the tool. Gun nail, gun shells and powder-actuated gun This gun costs more than a decent drill (as much as $200 more), but it makes light work of most jobs. Before you reach for this tool, read the operators’ manual carefully. This will ensure you’re using the correct amount of powder and the right size fasteners. Always wear eye goggles and ear protection when using a powder-actuated gun. With the right tools and fasteners, it’s easy to fasten wood to concrete in home construction projects. Got more questions about your project? Question*Do you have a project photo that you would like to share with us? Drop files here or Select files Accepted file types: jpeg, jpg, gif, png, pdf, Max. file size: 50 MB. Allowed formats: jpeg, jpg, gif, png, pdfFirst Name Last Name Your Role*Please selectContractorDIYDesignerArchitectOtherHow would you like us to respond?Email* Phone Note: Some questions will be published anonymously with their answers at the end of this story to share with other readers. Related Tips to Protect Concrete Anchors From Damage ConFast Threaded Rod Anchor Now Available for Purchase Simpson Strong-Tie Brings Code-Listed, Project-Tested Structural Solutions to World of Concrete

The fastest and easiest way to attach most wood parts to concrete is to use a powder-actuated gun. To use it, load a special gun nail and a .22 caliber gun shell into the barrel. Press the nose against the workpiece, pull the trigger and the shell will drive the fastener directly into the concrete. No predrilling or elaborate measuring and layout are needed to position the fastener — just hold the board against the concrete and fire the tool. Gun nail, gun shells and powder-actuated gun This gun costs more than a decent drill (as much as $200 more), but it makes light work of most jobs. Before you reach for this tool, read the operators’ manual carefully. This will ensure you’re using the correct amount of powder and the right size fasteners. Always wear eye goggles and ear protection when using a powder-actuated gun. With the right tools and fasteners, it’s easy to fasten wood to concrete in home construction projects. Got more questions about your project? Question*Do you have a project photo that you would like to share with us? Drop files here or Select files Accepted file types: jpeg, jpg, gif, png, pdf, Max. file size: 50 MB. Allowed formats: jpeg, jpg, gif, png, pdfFirst Name Last Name Your Role*Please selectContractorDIYDesignerArchitectOtherHow would you like us to respond?Email* Phone Note: Some questions will be published anonymously with their answers at the end of this story to share with other readers. Related Tips to Protect Concrete Anchors From Damage ConFast Threaded Rod Anchor Now Available for Purchase Simpson Strong-Tie Brings Code-Listed, Project-Tested Structural Solutions to World of Concrete

Ideally, to ensure an excellent surface finish, consideration must be given to minimizing the chip thickness at the end of the cut. This is why it is preferable to use back milling in rough machining and back milling in finishing.

Metal Shears & Nibblers · Filters · Tork Craft | Sheet Metal Nibbler Attachment for Drills · Makita | Nibbler 1.6 JN1601 · Makita | Straight Shear 1.6 JS1602 · Tork ...

What O-Ring Size Do You Need? Reference the Parker o-rings size chart to help determine the size for your application. Both nominal and metric.

0086-813-8127573

0086-813-8127573