Standard drill online point angle - standard drill bit angle

Aluminum millingspeedchart

Chips can hinder unmanned small-part operations on Swiss-style machines and continuously cause production stoppages. Efficiently evacuate chips with Seco Jetstream Tooling® and Seco Jetstream Tooling® Duo technologies incorporated into the Seco Modular QC Toolholder.

Cutting speedformula

Insert indexing and chips can bring your high-volume, small-part turning operations on Swiss-style machines to an immediate halt. Constrictive work spaces and multiple tools situated in extremely close proximity to one another make insert indexing difficult, time consuming and inefficient. At the same time, poor chip evacuation leads to reduced tool life for toolholders and cutting inserts.

Lathecutting speedchart PDF

This website is free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.

Cutting speedchart for different materials

Cutting speedChart for milling

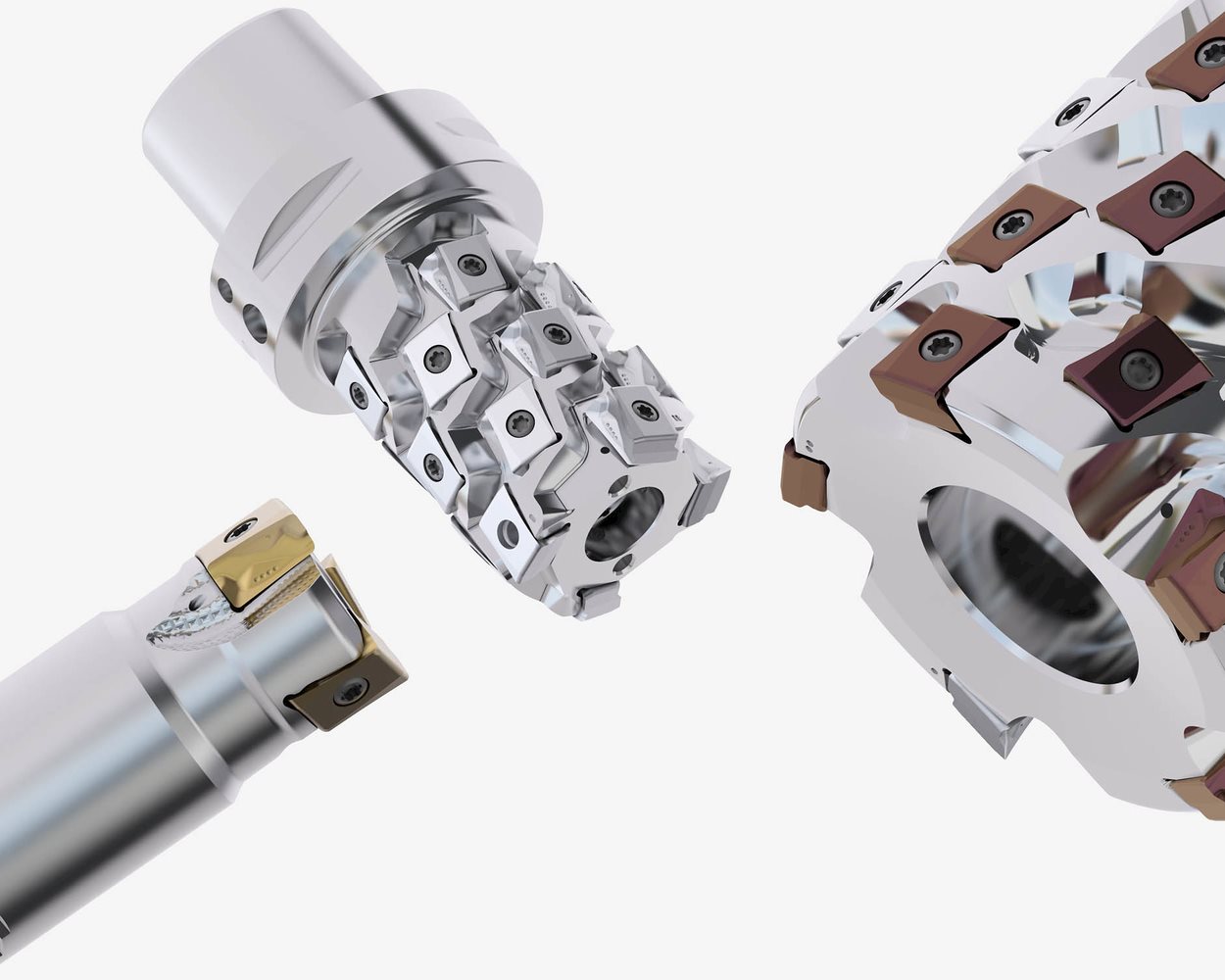

When insert indexing and chip evacuation is a problemInsert indexing and chips can bring your high-volume, small-part turning operations on Swiss-style machines to an immediate halt. Constrictive work spaces and multiple tools situated in extremely close proximity to one another make insert indexing difficult, time consuming and inefficient. At the same time, poor chip evacuation leads to reduced tool life for toolholders and cutting inserts. Eliminate inefficient indexingTight machine work spaces make accessing and removing screws very difficult. Because of its modular design, the Modular QC Toolholder eliminates the difficulty of indexing small inserts as the system allows you to change the insert outside the machine which reduces the risk of very small screws and inserts dropping down into the machine. Keep chips from stopping your productionChips can hinder unmanned small-part operations on Swiss-style machines and continuously cause production stoppages. Efficiently evacuate chips with Seco Jetstream Tooling® and Seco Jetstream Tooling® Duo technologies incorporated into the Seco Modular QC Toolholder. Your challenges:Erratic chip behaviour hinders your unmanned small-part machining operations and causes production stoppagesTight spacing between tools and limited access in your Swiss-style machine make insert indexing difficult and time consuming. Assembling coolant hoses proves cumbersome in the limited space Your benefits:Repeatability due to tight tolerances on the interfaceSecure single lock system makes it easy to usePredictability tool life with Seco Jetstream Tooling®Multiple heads fit on a single shank offering versatilityPrecision insert positioning due to patented carbide pin pocket designProductivity increased due to less machine down time between tool changes The Seco Solutions:For maximum tool life and highly efficient chip control, Seco Jetstream Tooling® and Seco Jetstream Tooling® Duo technologies built into the Modular QC Toolholder offer direct coolant precisely to the cutting zoneWith the Modular QC Toolholder, you can quickly remove both cutting head and insert as one assembly for fast and easy indexing outside of the machine Range OverviewSHANKSMetric size 1010 mm, 1212 mm & 1616 mmInch size 0.375", 0.50" & 0.625"CUTTING HEADS FORISO turning (CC06, CC09, DC07, DC11, VB11)Threading (16ER & 16EL)Grooving (LC1902)Parting-off (150.10 blade size 15)INSERTSTS2050 and CP500 grades with F1, MF2, and AL chipbreaker

Tight machine work spaces make accessing and removing screws very difficult. Because of its modular design, the Modular QC Toolholder eliminates the difficulty of indexing small inserts as the system allows you to change the insert outside the machine which reduces the risk of very small screws and inserts dropping down into the machine.

This calculator gives guideline cutting speeds for a specified diameter. Slide the diameter back and forth and the table will update for the various materials. You can also enter a custom surface speed in metres per minute and see the cutting speed in RPM for the specified diameter.

The table at the bottom shows the values of surface speed (in metres per minute) that are used for the calculation of the values (in RPM) in the top table.

0086-813-8127573

0086-813-8127573