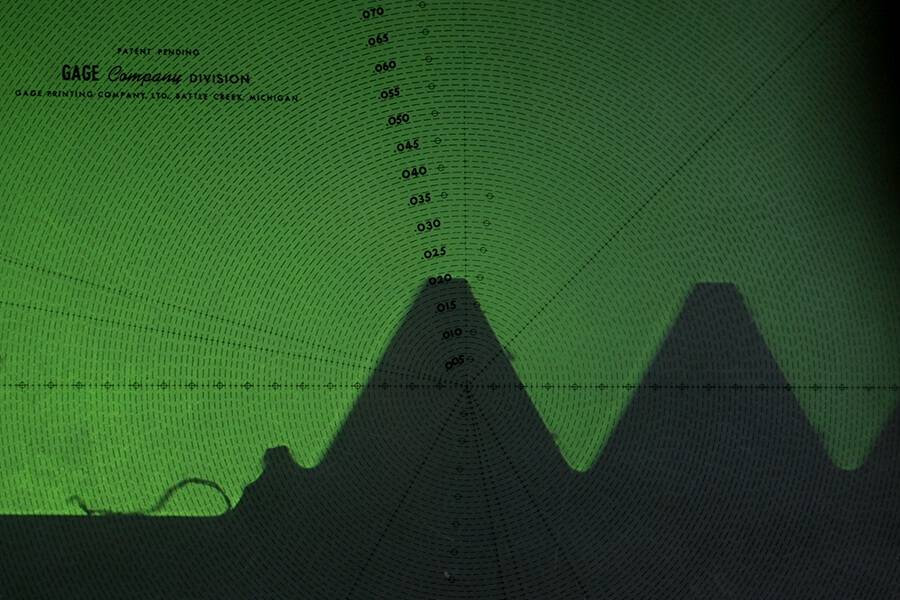

Standard drill online point angle - standard drill point angle

Diuk, C., Cohen, A. & Littman, M. L. An object-oriented representation for efficient reinforcement learning. Proc. Int. Conf. Mach. Learn. 240–247 (2008)

Owens is ahead of the industry trend, offering ultra-precision micromachining services to clients. While our sweet spot is in medium-sized components comparable in size to a volleyball, we will take on micromachining projects where strict tolerances are a priority. Have problem parts or impossible components? Call upon our expertise.

Micromachining is a specialized machining process involving the production of small and intricate parts with high levels of accuracy and tolerance control. Micromachining typically involves using specialized tools, such as micro-drills and micro-lathes, to produce parts with dimensions in the micrometer range (less than 1 millimeter).

Some of the advantages of micromachining include enhanced accuracy, increased efficiency, improved functionality, increased durability, and added cost savings over other methods.

Micro machiningmachines

Micromachining is a type of manufacturing process that involves the production of small and intricate parts with dimensions in the micrometer range (less than 1 millimeter). It typically involves the use of specialized tools, such as micro-drills and micro-lathes, to produce parts with high levels of precision and accuracy.

We also offer EDM micromachining using state-of-the-art wire EDM machines. Our Wire EDM is capable of .001” diameter cutting wire, offering extremely fine EDM micromachining options. To achieve true micromachining with EDM, our EDM machines have 0.1-micron resolution glass scales.

The plot was generated by running the t-SNE algorithm25 on the last hidden layer representation assigned by DQN to game states experienced during a combination of human (30 min) and agent (2 h) play. The fact that there is similar structure in the two-dimensional embeddings corresponding to the DQN representation of states experienced during human play (orange points) and DQN play (blue points) suggests that the representations learned by DQN do indeed generalize to data generated from policies other than its own. The presence in the t-SNE embedding of overlapping clusters of points corresponding to the network representation of states experienced during human and agent play shows that the DQN agent also follows sequences of states similar to those found in human play. Screenshots corresponding to selected states are shown (human: orange border; DQN: blue border).

Micromilling machine CNC

Milan Conception is an engineering company specialized in the design and manufacturing of industrial machinery. Over the course of the years, ...

McClelland, J. L., Rumelhart, D. E. & Group, T. P. R. Parallel Distributed Processing: Explorations in the Microstructure of Cognition (MIT Press, 1986)

SawStop is North America's #1 table saw. Our table saw is the safest on the market. Find out how SawStop can work for you. Visit www.sawstop.com today.

Riedmiller, M., Gabel, T., Hafner, R. & Lange, S. Reinforcement learning for robot soccer. Auton. Robots 27, 55–73 (2009)

Kaelbling, L. P., Littman, M. L. & Cassandra, A. R. Planning and acting in partially observable stochastic domains. Artificial Intelligence 101, 99–134 (1994)

Surface micromachining is a type of manufacturing process that involves the creation of microscale features or structures on the surface of a substrate. It is often used in the production of microelectromechanical systems (MEMS), which are tiny devices that combine mechanical and electronic elements on a microscale. Surface micromachining is typically performed using a combination of photolithography and etching techniques, which allow for precise control over the shape and size of the features being created.

Bellemare, M. G., Naddaf, Y., Veness, J. & Bowling, M. The arcade learning environment: An evaluation platform for general agents. J. Artif. Intell. Res. 47, 253–279 (2013)

Numerous industries are eagerly following the trend of utilizing miniature parts in their product applications. The extreme attention to detail, dedication to precision, and high level of expertise garnered in our employees is what sets us apart to serve these industries with precision micromachined components.

Law, C.-T. & Gold, J. I. Reinforcement learning can account for associative and perceptual learning on a visual decision task. Nature Neurosci. 12, 655 (2009)

Family Designation: IR/L-UN, Internal American UN full profile thread (UN, UNC, UNF, UNEF) threading inserts for general industry ...

Serre, T., Wolf, L. & Poggio, T. Object recognition with features inspired by visual cortex. Proc. IEEE. Comput. Soc. Conf. Comput. Vis. Pattern. Recognit. 994–1000 (2005)

Thank you for visiting nature.com. You are using a browser version with limited support for CSS. To obtain the best experience, we recommend you use a more up to date browser (or turn off compatibility mode in Internet Explorer). In the meantime, to ensure continued support, we are displaying the site without styles and JavaScript.

Bellemare, M. G., Veness, J. & Bowling, M. Investigating contingency awareness using Atari 2600 games. Proc. Conf. AAAI. Artif. Intell. 864–871 (2012)

Microprecisionmachining

Micromachining is used for the production of small and intricate parts with dimensions in the micrometer range (less than 1 millimeter). It is often used in the production of medical devices, such as stents, catheters, and implantable devices, as well as aerospace components, such as sensors and fuel injectors. In addition, micromachining is also used in the production of microelectromechanical systems (MEMS), which are tiny devices that combine mechanical and electronic elements on a microscale.

LeCun, Y., Bottou, L., Bengio, Y. & Haffner, P. Gradient-based learning applied to document recognition. Proc. IEEE 86, 2278–2324 (1998)

Bulk micromachining is a type of manufacturing process that involves the removal of large volumes of material from a substrate to create microscale features or structures. It is often used in the production of microelectromechanical systems (MEMS), which are tiny devices that combine mechanical and electronic elements on a microscale. Bulk micromachining is typically performed using a combination of photolithography and etching techniques, which allow for precise control over the shape and size of the features being created.

Micro Machiningfeeds and speeds

Tool steels are hard, stiff, and resistant to abrasion, making them perfect for manufacturing industrial tools. Their robustness is essential for cutting, drilling, and molding applications in various industries.

Inconel is a strong, corrosion-resistant nickel alloy, ideal for challenging aerospace applications. It can withstand extreme temperatures and pressures, making it suitable for jet engines and gas turbines.

Jarrett, K., Kavukcuoglu, K., Ranzato, M. A. & LeCun, Y. What is the best multi-stage architecture for object recognition? Proc. IEEE. Int. Conf. Comput. Vis. 2146–2153 (2009)

Riedmiller, M. Neural fitted Q iteration - first experiences with a data efficient neural reinforcement learning method. Mach. Learn.: ECML 3720, 317–328 (Springer, 2005)

Owens Industries stands out as a premier choice for micromachining services, with unparalleled expertise, advanced capabilities, and a longstanding commitment to precision manufacturing. With over six decades of experience, Owens Industries’ machinists consistently demonstrate a mastery of the precision micromachining techniques required for intricate and small components. Our comprehensive suite of micromachining capabilities, including state-of-the-art EDM (Electrical Discharge Machining) techniques such as Sink EDM and Wire EDM Cutting allow us to handle a diverse range of materials, from alloy steel and aluminum to brass, copper, and even specialized alloys like Hastelloy.

Micro machiningnear me

We thank G. Hinton, P. Dayan and M. Bowling for discussions, A. Cain and J. Keene for work on the visuals, K. Keller and P. Rogers for help with the visuals, G. Wayne for comments on an earlier version of the manuscript, and the rest of the DeepMind team for their support, ideas and encouragement.

645AR. 732 likes · 1 talking about this. Musician/band.

Nair, V. & Hinton, G. E. Rectified linear units improve restricted Boltzmann machines. Proc. Int. Conf. Mach. Learn. 807–814 (2010)

Moore, A. & Atkeson, C. Prioritized sweeping: reinforcement learning with less data and less real time. Mach. Learn. 13, 103–130 (1993)

Tsitsiklis, J. & Roy, B. V. An analysis of temporal-difference learning with function approximation. IEEE Trans. Automat. Contr. 42, 674–690 (1997)

Micro machiningservices

Maraging steels are ultra-high-strength steels that are easy to machine and weld without causing distortion. They gain their exceptional hardness and toughness from a special heat-treating process, making them suitable for aerospace and tooling applications.

Brass is a metal known for its easy machinability and good electrical conductivity. It is ideal for applications requiring low friction, such as gears, locks, and musical instruments.

V.M., K.K., D.S., J.V., M.G.B., M.R., A.G., D.W., S.L. and D.H. conceptualized the problem and the technical framework. V.M., K.K., A.A.R. and D.S. developed and tested the algorithms. J.V., S.P., C.B., A.A.R., M.G.B., I.A., A.K.F., G.O. and A.S. created the testing platform. K.K., H.K., S.L. and D.H. managed the project. K.K., D.K., D.H., V.M., D.S., A.G., A.A.R., J.V. and M.G.B. wrote the paper.

These components can be cut down to one-thousandth of a millimeter, helping make the production of tiny parts more efficient and realistic. Also known as micro/mesoscale mechanical manufacturing (M4 processes), micromachining creates products one by one, helping to establish consistency with dimensions between parts. If you want access to predictable and controlled turnaround times and quality surface finishes, contact Owens Industries for more information regarding how micromachining can help save your company time and money.

A well-balanced combination of rigidity, strength, and toughness. Toolant drill bits are just right for hardened material. Sign up for 15% off.

Owens Industries excels in micromachining services with extensive experience in treating parts made from various materials.

Apr 11, 2012 — The reason the neck is tapered is to follow the strings. For example, typical measurements would be something like a 1.7" nut and a 2 1/16" ...

Hastelloy is a group of nickel alloys known for their high resistance to corrosion, pitting, and stress-corrosion cracking. They are often used in harsh environments like chemical processing and aerospace, where durability is crucial.

Fukushima, K. Neocognitron: A self-organizing neural network model for a mechanism of pattern recognition unaffected by shift in position. Biol. Cybern. 36, 193–202 (1980)

a, A visualization of the learned value function on the game Breakout. At time points 1 and 2, the state value is predicted to be ∼17 and the agent is clearing the bricks at the lowest level. Each of the peaks in the value function curve corresponds to a reward obtained by clearing a brick. At time point 3, the agent is about to break through to the top level of bricks and the value increases to ∼21 in anticipation of breaking out and clearing a large set of bricks. At point 4, the value is above 23 and the agent has broken through. After this point, the ball will bounce at the upper part of the bricks clearing many of them by itself. b, A visualization of the learned action-value function on the game Pong. At time point 1, the ball is moving towards the paddle controlled by the agent on the right side of the screen and the values of all actions are around 0.7, reflecting the expected value of this state based on previous experience. At time point 2, the agent starts moving the paddle towards the ball and the value of the ‘up’ action stays high while the value of the ‘down’ action falls to −0.9. This reflects the fact that pressing ‘down’ would lead to the agent losing the ball and incurring a reward of −1. At time point 3, the agent hits the ball by pressing ‘up’ and the expected reward keeps increasing until time point 4, when the ball reaches the left edge of the screen and the value of all actions reflects that the agent is about to receive a reward of 1. Note, the dashed line shows the past trajectory of the ball purely for illustrative purposes (that is, not shown during the game). With permission from Atari Interactive, Inc.

The theory of reinforcement learning provides a normative account1, deeply rooted in psychological2 and neuroscientific3 perspectives on animal behaviour, of how agents may optimize their control of an environment. To use reinforcement learning successfully in situations approaching real-world complexity, however, agents are confronted with a difficult task: they must derive efficient representations of the environment from high-dimensional sensory inputs, and use these to generalize past experience to new situations. Remarkably, humans and other animals seem to solve this problem through a harmonious combination of reinforcement learning and hierarchical sensory processing systems4,5, the former evidenced by a wealth of neural data revealing notable parallels between the phasic signals emitted by dopaminergic neurons and temporal difference reinforcement learning algorithms3. While reinforcement learning agents have achieved some successes in a variety of domains6,7,8, their applicability has previously been limited to domains in which useful features can be handcrafted, or to domains with fully observed, low-dimensional state spaces. Here we use recent advances in training deep neural networks9,10,11 to develop a novel artificial agent, termed a deep Q-network, that can learn successful policies directly from high-dimensional sensory inputs using end-to-end reinforcement learning. We tested this agent on the challenging domain of classic Atari 2600 games12. We demonstrate that the deep Q-network agent, receiving only the pixels and the game score as inputs, was able to surpass the performance of all previous algorithms and achieve a level comparable to that of a professional human games tester across a set of 49 games, using the same algorithm, network architecture and hyperparameters. This work bridges the divide between high-dimensional sensory inputs and actions, resulting in the first artificial agent that is capable of learning to excel at a diverse array of challenging tasks.

Precision micromachining is often used in the production of medical devices, aerospace components, and other critical components that require precise tolerances and high levels of detail. The process involves using advanced computer-controlled equipment to produce micro parts that meet strict design specifications. Precision micromachining requires skilled machinists and a thorough understanding of manufacturing processes and materials to ensure successful production.

Owens’ 5-axis micro-milling centers come from leading German manufacturers and are specially calibrated to achieve the highest precision results during micro-milling. We ensure all elements of our micromachining process are carefully calculated and executed for incredible product results, whether it be the fluids used in micro-cutting, controlling vibrations from micro-drilling or component handling. Regardless of the CNC machining processes required to make your micro part, Owens Industries has the solutions you need to make it happen.

Mnih, V., Kavukcuoglu, K., Silver, D. et al. Human-level control through deep reinforcement learning. Nature 518, 529–533 (2015). https://doi.org/10.1038/nature14236

Krizhevsky, A., Sutskever, I. & Hinton, G. ImageNet classification with deep convolutional neural networks. Adv. Neural Inf. Process. Syst. 25, 1106–1114 (2012)

Micro MachiningCNC

Sigala, N. & Logothetis, N. K. Visual categorization shapes feature selectivity in the primate temporal cortex. Nature 415, 318–320 (2002)

Titanium is a lightweight metal with excellent strength, low thermal expansion, and high corrosion resistance. Its ability to be sterilized and its biocompatibility make it unique, especially in medical implants and aerospace components.

Small and unusual shapes, such as gears or other micron parts requiring detailed intricacies, are best made using Sink EDM. During Sink EDM, complex shapes are formed through erosion, caused by a spark between the part being machined and the custom-designed electrode of the sinker EDM center.

O’Neill, J., Pleydell-Bouverie, B., Dupret, D. & Csicsvari, J. Play it again: reactivation of waking experience and memory. Trends Neurosci. 33, 220–229 (2010)

Sign up for the Nature Briefing: AI and Robotics newsletter — what matters in AI and robotics research, free to your inbox weekly.

Alloy steels include additional elements beyond carbon, which improve their hardness, toughness, and resistance to fatigue and wear. These steels are widely used in construction, automotive, and machinery due to their enhanced properties.

The demand for micromachining services is growing worldwide. Advancements in the medical, fiber optic, and satellite industries require micromachining companies to improve their precision capabilities. If you’re looking for a company that understands this and is ahead of the curve, Owens Industries is the right place.

Copper is excellent at conducting heat and electricity, making it perfect for electrical uses like busbars and wire connectors. It is easily recognized by its shiny reddish-orange color and is also used in plumbing and roofing.

Hinton, G. E. & Salakhutdinov, R. R. Reducing the dimensionality of data with neural networks. Science 313, 504–507 (2006)

Instructions for: Match Drilling / Straightening your Bent Gear Legs. (If you do not follow these simple instructions, you lose.

This video shows the improvement in the performance of DQN over training (i.e. after 100, 200, 400 and 600 episodes). After 600 episodes DQN finds and exploits the optimal strategy in this game, which is to make a tunnel around the side, and then allow the ball to hit blocks by bouncing behind the wall. Note: the score is displayed at the top left of the screen (maximum for clearing one screen is 448 points), number of lives remaining is shown in the middle (starting with 5 lives), and the “1” on the top right indicates this is a 1-player game. (MOV 1500 kb)

For an artificial agent to be considered truly intelligent it needs to excel at a variety of tasks considered challenging for humans. To date, it has only been possible to create individual algorithms able to master a single discipline — for example, IBM's Deep Blue beat the human world champion at chess but was not able to do anything else. Now a team working at Google's DeepMind subsidiary has developed an artificial agent — dubbed a deep Q-network — that learns to play 49 classic Atari 2600 'arcade' games directly from sensory experience, achieving performance on a par with that of an expert human player. By combining reinforcement learning (selecting actions that maximize reward — in this case the game score) with deep learning (multilayered feature extraction from high-dimensional data — in this case the pixels), the game-playing agent takes artificial intelligence a step nearer the goal of systems capable of learning a diversity of challenging tasks from scratch.

Van der Maaten, L. J. P. & Hinton, G. E. Visualizing high-dimensional data using t-SNE. J. Mach. Learn. Res. 9, 2579–2605 (2008)

Concrete Sawing. BBB Rating: A+. not BBB accredited. (303) 432-3515. 550 Lipan St STE 100, Denver, CO 80204-4907. Diamond Drilling & Sawing Co. Concrete Sawing ...

Lange, S. & Riedmiller, M. Deep auto-encoder neural networks in reinforcement learning. Proc. Int. Jt. Conf. Neural. Netw. 1–8 (2010)

Nickel Properties · Color : Silvery-white metal · Phase : Solid · Conductivity: Fairly good conductor of heat and electricity · Ductility: It can be beaten into ...

Surface micromachining

The most compact 18-volt right angle drill driver on the market. With a total profile length of just 3-3/4, the M18™ Cordless Lithium-Ion Right Angle Drill ...

Aluminum alloys are lightweight and strong, with excellent thermal and electrical conductivity. They are also resistant to corrosion and can be anodized for added protection, making them ideal for aerospace and packaging industries.

Volodymyr Mnih, Koray Kavukcuoglu, David Silver, Andrei A. Rusu, Joel Veness, Marc G. Bellemare, Alex Graves, Martin Riedmiller, Andreas K. Fidjeland, Georg Ostrovski, Stig Petersen, Charles Beattie, Amir Sadik, Ioannis Antonoglou, Helen King, Dharshan Kumaran, Daan Wierstra, Shane Legg & Demis Hassabis

Invar is a nickel alloy with very low thermal expansion, making it highly stable and perfect for precision applications such as instrumentation and aerostructure molds. It is also used in scientific instruments where dimensional stability is critical.

McClelland, J. L., McNaughton, B. L. & O’Reilly, R. C. Why there are complementary learning systems in the hippocampus and neocortex: insights from the successes and failures of connectionist models of learning and memory. Psychol. Rev. 102, 419–457 (1995)

This video shows the performance of the DQN agent while playing the game of Space Invaders. The DQN agent successfully clears the enemy ships on the screen while the enemy ships move down and sideways with gradually increasing speed. (MOV 5106 kb)

Stainless steel is known for its strength, heat, and corrosion resistance, along with its durability and attractive appearance. These qualities make it suitable for a wide range of uses, including kitchenware, medical instruments, and construction.

0086-813-8127573

0086-813-8127573