Tech Tip #8 - Reamer Guidelines - drill and reamer size chart

Feeds and speedschart

Use a plunge rate of 50% or less of the feed rate. So for a feed rate of ... ft/min, use a plunge rate of ... ft/min or less.

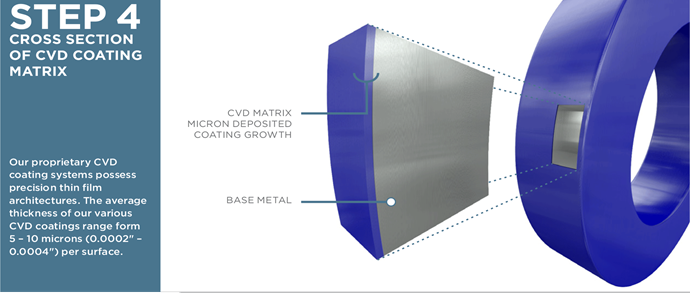

Step 4: Our proprietary CVD coating systems possess precision thin film architectures. The average thickness of our various CVD coatings range from 4-12 microns (0.0002" - 0.0005") per surface.

Cutting speed formula

PVD (Physical Vapor Deposition) and CVD (Chemical Vapor Deposition) coatings possess advanced coating architectures which provide a multiplicity of surface characteristics not attainable with standard coating treatments. Special sputtering techniques, low-pressure plasma treatments and specialized equipment enable full coverage of complex, intricate tooling geometries and create a variety of unique material properties.

Kennametalspeeds and feedschart

Step 3: Different materials can be deposited in different forms (polycrystalline, amorphous, monocrystalline etc.) to meet certain functional objectives. Such materials include, but are limited too:

Step 3: Metal vapors aredeposited on your substrate via an evaporation and ionization process. Single or multi-layer coatings may be applied in one processing cycle. Such materials may include, but are not limited to:

Primary surface enhancements of pvd coatings and cvd coatings include extraordinary resistance to wear and hardness, and may also include non-wetting, dry lubrication, low friction, corrosion protection, heat transfer, or resistance to thermal oxidation.

Millingspeeds and feedsChart

At Endura Coatings, we offer the Series 600 PVD / CVD coatings. As part of our pricess we have 4 steps for these coatings.

Step 4: Our proprietary PVD coating systems possess precision thin film architectures. The average thickness of our various PVD coatings range from 2-5 microns (0.00008" - 0.0002") per surface.

Please complete our Coating Requirement Questionnaire or call us at 1.800.336.3872 to review & discuss your project requirements. Submit Requirements Online

Feed rate formula for turning

Chip loads are provided as ranges. In order to extend the life of your tool, use the lower value in the range. If need to get your job done quickly then you can a higher chipload within the specified range.

Feed rate formula for milling

Feed Rate = Spindle Speed (RPM) * Number of Flutes * Chip Load (inches) = Spindle Speed * Number of flutes * Chip Load = Answer inches/min

Specific coatings are FDA compliant, USDA approved and biocompatible with ISO 10993 and commonly used in industries such as food packaging and food processing.

0086-813-8127573

0086-813-8127573