The Ultimate Guide to Understanding the Difference Between ... - milling machine vs drill press

2014320 — Alpha Iron and ferrite – Fully ferritic steels are obtained only when the carbon content is low. The most obvious micro-structural features are ...

Carbide saw bladesharpening service near me

When figuring out these two parameters to preprogram into the CNC lathe, the hardness of the metal and how rigid the workpiece is must be taken into account. If using too high of a cutting speed or feed for a soft metal, the tool may end up removing too much in one pass. Cutting a hard metal at too low of a speed or feed rate may not provide the desired surface finish. One key aspect to keep in mind is that the tool’s speed must increase when the hardness and strength of the metal increases.

How to sharpena circularsaw bladeby hand

Choose from our selection of carbide tipped drill bits, including high-speed steel drill bits, cobalt steel drill bits, and more.

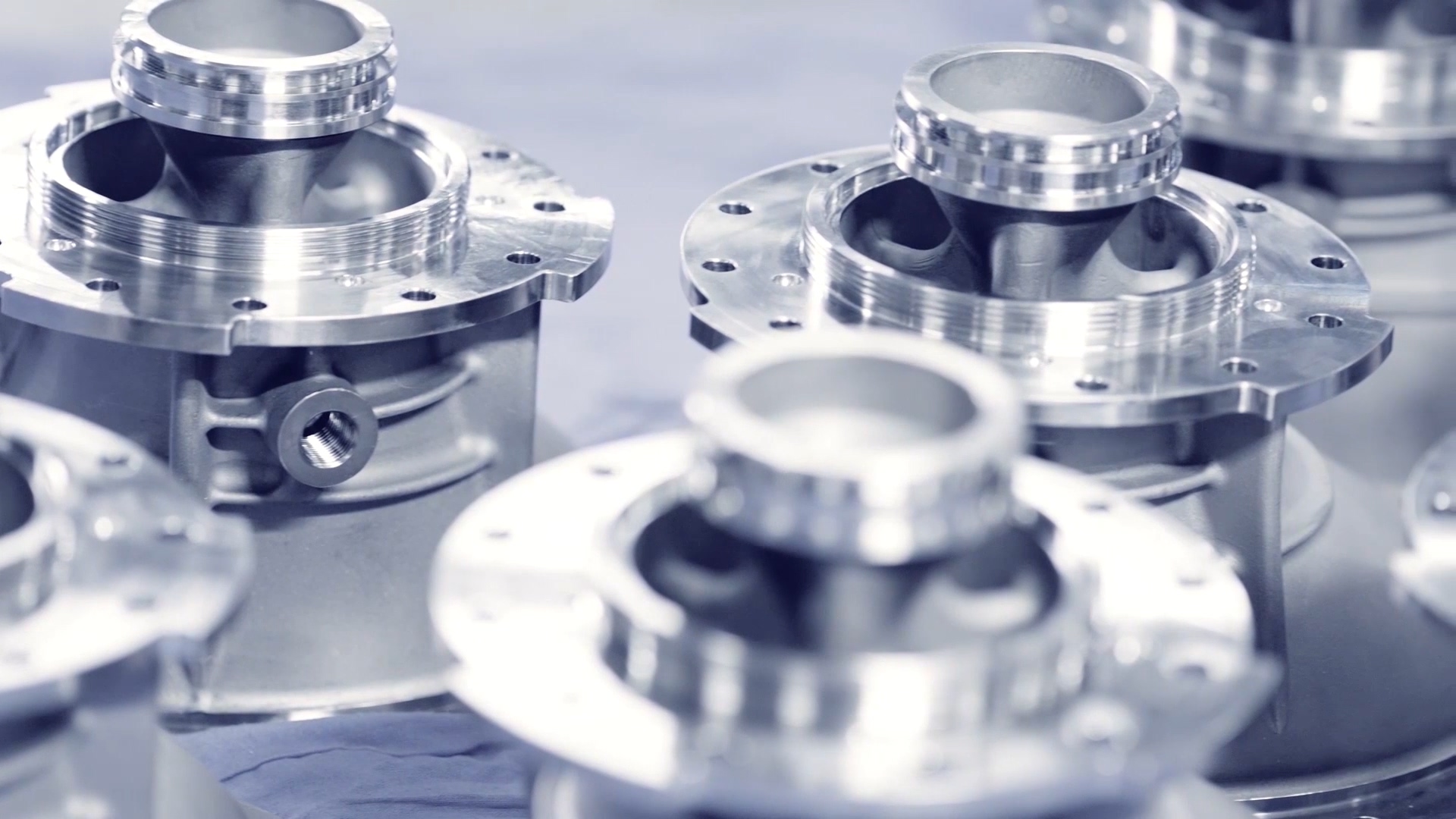

Hydraulic machines are used on industrial, commercial, and public applications to perform a range of tasks. They are found in heavy equipment, food processing, aircraft, and other equipment. To create hydraulic components, precision machine tools are often used. These consist of machine tools such as CNC lathes.

Determining the cutting speed for the precision machine is based on the peripheral speed of the workpiece when it is fed past the rotating cutting tool. This measurement is shown as feet per minute or meters per minute based on the cutting speed velocity. The cutting feed rate and the cutting speed helps to determine the power requirements of the tool to ensure it is moving at a rate that is appropriately defined based on how much material is cut away in one rotational pass.

How to sharpen carbide saw bladeby hand

Shoulder milling. Lineup of multifunctional, high-precision, high-efficiency shoulder cutting tools. Unique tools such as the Shoulder Extreme for

Our manufacturing capabilities cover the entire casting component production process, from tooling design and manufacturing, casting, secondary machining, heat treatment, surface treatment to finishing, enabling us to offer ready-to-use products and services to customers. overview:We offer comprehensive one-stop solutions that cover the precision component manufacture value chain throughout the entire product life cycle.

You can use a hand file, crank sharpener or automatic sharpener on saw blades you're going to sharpen yourself. While automatic sharpeners will get the job done faster, they can also be rough on your blade's teeth. They might overheat or lose the correct angle of the teeth they are sharpening. Although it requires more of your time and effort, filing your blades manually usually produces a better result.

Milling Formulas · Speed (RPM) = (SFM x 3.82) / D · Feed (IPM) = RPM x FPT x Z · SFM (Surface Feet per Minute) = (RPM x D) / 3.82 · IPT (Inches per Tooth) = (IPM / ...

The parameter impacts the performance and efficiency of the precision machining process. To select the right depth of cut, the following factors are taken into consideration:

Sand casting is a metal forming process in which a mold is first formed from a three-dimensional pattern of sand, and molten metal is poured into the mold cavity for solidification.

Significant improvements to the workpiece can be made with the use of a CNC lathe machine. A CNC lathe can make a rougher finish by having the preprogrammed machine lower the depth of the cut parameter. The machine may also remove more materials and speed up the production process with an increase to the depth of the cut parameter.

How to sharpen carbide saw bladeat home

These three parameters focus on how the hydraulic part is cut. Cutting speed represents how fast the metal is removed from the workpiece. Cutting feed focuses on how far the cutting spindle travels across the metal part during one full rotation of the tool. As the cutting tool moves into the metal part, the distance that it moves is the depth of cut. These three parameters ensure accuracy of the finished workpiece and the surface finish.

Saw bladesharpening near me

Surface treatment generally refers to a process to alter an object’s surface to enhance its appearance or functional properties. At Impro, surface treatment refers to electroplating, one of the most widely-used surface treatment techniques that provide broad coverage of coating metals and high cost-efficiency.

chamfer bit ; 2" Diamond Beveling Chamfer Cone Milling Bit Tile with Hex Adapter Countersink · $22.99. Was: $26.99was - US $26.99. or Best Offer. Free shipping.

Impro is an integrated one-stop solution providers. In addition to our primary manufacturing process technologies, we have other in-house casting processes such as permanent mold casting and shell mold casting to satisfy aerospace customers’ need for precision aluminum castings. At Impro manufacturing facilities, our comprehensive heat treatment and laboratory services can ensure products are processed timely in accordance with exact specifications and customer requirements.

How to sharpena circularsaw bladewith a file

Investment casting is a metal forming process that generally involves using a wax pattern surrounded by a ceramic shell to form a ceramic mold. Once the ceramic shell is dry, the wax is melted out, and the ceramic mold is formed.

How to sharpena tablesaw bladewith a file

Kitagawa Workholding Solutions. KITAGAWA products, Standard chuck. Advance chuck. Manual chuck. Rotary cylinder. NC rotary table.

Black Oxide Extended Length Drill Bit. HERCULES. 3/8 in. x 6 in. Black Oxide ... Related ProductsRelated Products. 5.30-12 in. Tire with 5 Lug Rim Load. A high ...

The depth of cut parameter focuses on the tertiary cutting motion of the tool as the tool is pushed deeper into the workpiece to the specified depth. This parameter is measured as thousandths of an inch or thousandths of millimeters. The depth of cut will usually vary between 0.1 to 1.0 mm.

Our range of tools for metal engraving and setting tools includes a fantastic array of micro carbide tooling bits such as carbide engraving bits in 30 degrees, ...

How to sharpencircularsaw blade

When your circular saw blade becomes dull, not only will it give you a rougher finish, but your saw's motor will have to work harder and may burn out sooner. Sharpening your saw blades will save you money in the long run because you'll get better cuts, and you'll have to replace your saw and blades less often.

CNC lathes minimize these issues with preprogrammed parameters that focus on the speed, feed, and depth of cut performed on the part.

Global trade policies, supply chain issues, transportation and shipping capacity shortage are among many factors that impact customers in different regions around the world. It can impede customer demand, slow down supply chain capabilities and raise costs. Localized production and near-sourcing are the growing trends. To offset the hurdles and provide more vertically integrated solutions to North American customers, Impro’s high precision machining and casting operations are expanding into Mexico.

Precision machining is a process to produce accurate components with high tolerances and excellent surface quality by removing materials from a workpiece. It involves a combination of several or all of the turning, milling, drilling, gear cutting, honing, grinding processes, and other steps.

Flute is a service performed in the manufacturing industry that involves the creation of grooves or channels on a surface.

Turning machines used to produce hydraulic parts provide immense benefits. These machines can produce hydraulic parts such as pistons and cylinder assemblies quickly while being cost-effective. The CNC lathe machine works by removing materials from the part at specific speeds as the equipment rotates the workpiece until reaching a specific depth. When creating the workpiece with precision machining processes, common issues such as friction, chip formation, heat generation or conductivity to the metal may occur. These problems may negatively impact the metal’s grain structure to cause damage, creating an inaccurate workpiece.

You can sharpen steel-toothed circular saw blades yourself using a file. Carbide-tipped blades need to be taken to a professional sharpening service for two reasons: Carbide is so hard that you need a diamond wheel sharpener for it, and sharpening carbide blades is so complicated that you can easily ruin the blade. Carbide blades cut not only with the tips of the teeth but also with the sides, and if you're not careful, you can end up rounding off these edges. A sharpening service will return your saw blades to like-new condition for about 25 to 50 cents per tooth. You should ask a professional about other types of blades because some cannot be re-sharpened, and some blades are so cheap it might not even be worth the expense to get them sharpened. But don't throw them out -- save them for demolition work or cutting up lumber that might have nails hidden in it.

MPN. 123603246. Insert Style. WNMG. Insert Size. 433. Material. Carbide. Insert Material. Carbide. Grade. AC810P. Insert Type. Turning Insert.

0086-813-8127573

0086-813-8127573