Tool # 72016 - Harvey - 72016

The mining industry uses tungsten carbide inserts in various tools to extract minerals and ores. The durability of these inserts ensures that they can handle the abrasive conditions found in mining environments.

Truer Carbides has supplied an extensive range of tungsten carbide grades with broad dimensions used for various of applications, including mining & construction, oil & gas, wear parts and also cutting/machining/milling tools.

Selecting the right manufacturer for tungsten carbide inserts can be a daunting task. Here’s a guide to help you navigate this process.

In the automotive industry, tungsten carbide inserts are used to manufacture various parts, including engine components and body panels. Their ability to withstand high temperatures and pressures makes them ideal for these applications.

Consider the material properties of the inserts. Do you need high hardness for cutting tough materials? Or perhaps you need high toughness for impact-resistant applications?

Manufacture tungsten carbide insertfor sale

Indexable inserts are the most common type. They’re designed to be replaced when worn, without the need to replace the entire tool. This makes them cost-effective and versatile.

By understanding these advantages and limitations, you can make a more informed decision when selecting tungsten carbide inserts for your specific application.

Contains HM Land Registry data © Crown copyright and database right 2024. This data is licensed under the Open Government Licence v3.0.

Tungsten carbide inserts are essential tools used in various industries, from machining to manufacturing. These inserts play a crucial role in cutting, shaping, and drilling hard materials. The combination of tungsten and carbon creates a compound that is incredibly hard, durable, and resistant to wear, making it ideal for high-stress applications. But what makes tungsten carbide so unique? How do you choose the right manufacturer for your needs? And what are the key factors to consider when selecting tungsten carbide inserts?

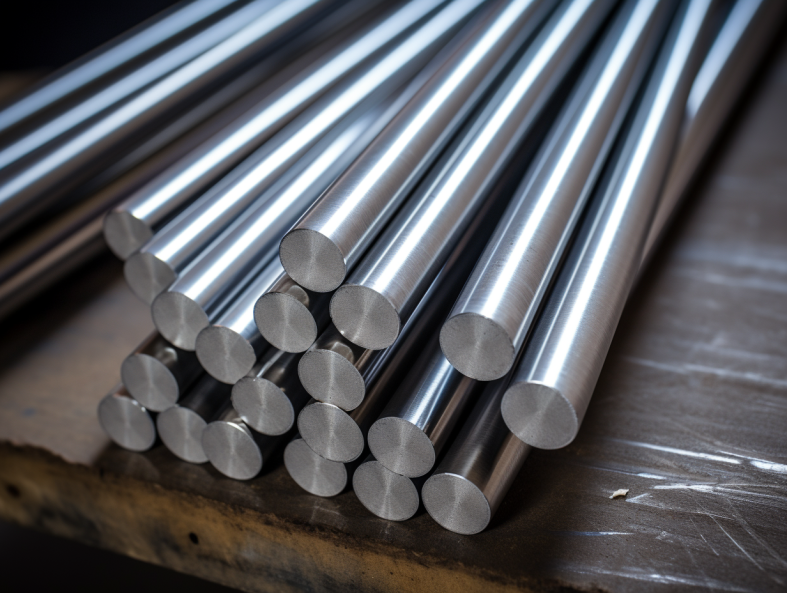

Solid carbide rods are a game-changer in industries that demand durability, precision, and efficiency in cutting tools, automotive components, and specialized manufacturing equipment. Known for their resilience, hardness, and wear

Tungsten carbide inserts are an essential tool in many industries, offering unparalleled hardness, wear resistance, and versatility. Whether you’re cutting metal, drilling through rock, or shaping wood, these inserts can provide the performance you need. By understanding the different types of inserts, their applications, and how to select the right manufacturer, you can ensure you’re making the best choice for your specific needs. Remember, the right tungsten carbide insert can make all the difference in your operation’s efficiency and success. So take the time to choose wisely, and invest in quality tools that will serve you well for years to come.

When it comes to tungsten carbide inserts, the type of metal powder used can significantly impact the final product’s performance. Here are some specific metal powder models commonly used:

Permitted Use: Viewers of this Information are granted permission to access this Crown copyright material and to download it onto electronic, magnetic, optical or similar storage media provided that such activities are for private research, study or in-house use only. Any other use of the material requires the formal written permission of Land Registry which can be requested from us, and is subject to an additional licence and associated charge.

In the drilling industry, these inserts are used in drill bits to cut through rock and other hard materials. Their wear resistance ensures that they can withstand the extreme conditions found in drilling operations.

In drilling operations, tungsten carbide inserts are used to create holes in tough materials. Their hardness and wear resistance make them ideal for this task.

Start by identifying the specific needs of your application. What materials will you be cutting? What kind of finish do you require? What are the operating conditions?

Tungsten carbide inserts come in various types, each designed for specific applications. Understanding the differences between these types can help you select the right one for your needs.

Kennametal

Tungsten carbide inserts are small cutting tools used in industrial machines. They’re designed to cut, shape, and mold various materials, including steel, iron, and even some ceramics. The magic lies in the material itself—tungsten carbide is a composite of tungsten and carbon atoms, combined to form a material that’s twice as stiff as steel and much denser.

Quality control is crucial in the manufacturing of tungsten carbide inserts. Look for manufacturers that have strict quality control measures in place, such as ISO certification.

Tungsten carbide inserts serve several key functions in industrial applications. Here’s a closer look at their primary roles.

Carbideinserts manufacturers

Consider whether the manufacturer specializes in the type of tungsten carbide inserts you need. A manufacturer with a broad product range may offer more options, but one that specializes in your specific area may provide better performance.

Ultra metCarbideTechnologies

Compare the prices of different inserts, but also consider the value. A higher-priced insert might offer better performance and longer life, leading to lower costs over time.

When it comes to purchasing tungsten carbide inserts, the choice of supplier can impact both the quality and cost. Here’s a look at some reputable suppliers and their pricing details.

Choosing the right tungsten carbide inserts is a critical decision that can impact your productivity, costs, and overall success. Here’s a step-by-step guide to help you make the right choice.

Tungsten carbide inserts are used in various industries due to their versatility and durability. Here’s a look at some of the common applications.

These properties make tungsten carbide inserts suitable for a wide range of applications, particularly those involving high stress, high temperatures, and abrasive conditions.

Some manufacturers offer specialty inserts designed for specific materials or applications, such as high-precision cutting or heavy-duty milling.

Start by researching the manufacturer’s reputation. Look for customer reviews, industry awards, and any certifications that indicate a commitment to quality.

Tungsten carbide inserts are also used in milling operations, where they help shape materials with high precision. Their ability to maintain sharpness over time makes them ideal for these applications.

Ultra metcarbidegrades

Even in woodworking, tungsten carbide inserts are used in tools that cut and shape wood. Their ability to stay sharp longer than steel tools makes them a preferred choice.

These suppliers are known for their quality products, and while prices may vary, they generally offer good value for the performance you receive.

Each of these metal powder models offers specific benefits, making them suitable for different applications. For example, WC-Co is widely used in general machining, while WC-Ni might be preferred in environments where corrosion resistance is critical.

Selecting the right manufacturer is crucial. Quality can vary significantly between manufacturers, and a poorly made insert can lead to tool breakage, poor finish quality, and higher costs. Factors such as the purity of the raw materials, precision in manufacturing, and the quality control processes in place all play a significant role in determining the final product’s performance.

This guide will dive deep into the world of tungsten carbide inserts, exploring everything from specific metal powder models to the characteristics, applications, and selection process. Whether you’re a seasoned professional or just beginning to explore this field, this comprehensive article will provide you with the knowledge you need.

Carbide plates are essential components in a variety of industries, including manufacturing, mining, and metalworking. Known for their exceptional hardness, wear resistance, and durability, carbide plates are the go-to solution

Manufacture tungsten carbide insertin usa

The world of machining and manufacturing is filled with advanced tools and materials that boost productivity, precision, and durability. One such innovative product is the helical coolant holes carbide rod.

The primary function of tungsten carbide inserts is cutting. Whether it’s metal, wood, or other materials, these inserts are designed to cut with precision and efficiency.

Tungsten carbide inserts come in various sizes and shapes to meet different application needs. Here’s a detailed look at the specifications.

Tungsten carbide inserts are also used for shaping materials. In milling operations, for example, they help create specific shapes and contours with high precision.

When it comes to industrial and machining applications, end chamfered ground carbide rods are a key material. These rods combine advanced metallurgy with precision engineering to provide robust performance in

These inserts have a coating (often titanium carbide or titanium nitride) to increase their hardness and wear resistance. The coating can significantly extend the insert’s life.

Ultra metcarbidetechnologies linkedin

Consider the level of customer support and service offered by the manufacturer. This includes technical assistance, availability of replacement parts, and the ability to provide custom solutions.

Finally, tungsten carbide inserts are often used in finishing operations. They can create smooth surfaces and fine finishes, making them essential in industries like automotive and aerospace.

This material was last updated on 16 October 2024. It covers the period from 1 January 1995 to 30 August 2024 and contains property transactions which have been registered during that period.

If possible, test the inserts in your specific application before making a large purchase. This will help you validate your choice and ensure it meets your needs.

While cost is an important factor, it’s essential to consider the value you’re getting for your money. Cheaper inserts may save you money upfront but could lead to higher costs in the long run due to lower performance or shorter lifespan.

Brazed inserts are permanently attached to the tool. They offer a solid, stable performance but require replacement of the entire tool once the insert wears out.

Understanding the material properties of tungsten carbide inserts is essential for selecting the right one for your application. Here’s a breakdown of the key properties.

Uncoated inserts are pure tungsten carbide. They’re ideal for specific applications where coatings might not provide additional benefits.

In machining, tungsten carbide inserts are used for cutting and shaping metals. Their hardness allows them to cut through tough materials like steel and cast iron with ease.

The composition of tungsten carbide inserts is a key factor in their performance. Here’s a look at the typical composition and characteristics.

These specifications allow manufacturers to produce inserts that meet the specific needs of different industries and applications.

Look at what different manufacturers offer. Do they have the specific type of insert you need? Do they offer custom solutions if necessary?

Choosing the right tungsten carbide inserts involves considering various factors. Here’s a guide to help you make the right choice.

These components are carefully selected and combined to create tungsten carbide inserts that offer a balance of hardness, toughness, and wear resistance.

0086-813-8127573

0086-813-8127573