Whittet-Higgins Recommended Threaded Shaft Dimensions - theoretical machinist thread

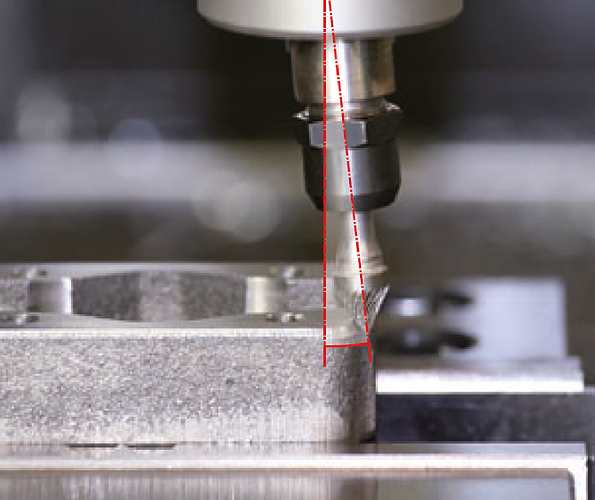

Our cumulative experience of more than 40 years has showed us that every company suffers with one common problem, Burrs. When you drill holes, you a lot of burrs. And then you deburr those holes with hand tools. We have developed patented plunge-type tools for finishing your holes, so that you can manufacture burr-free components without any off-line process starting at 1.45mm diameter.

A lot of components in the industry have counter bores or spot faces on the front as well as the back surfaces of a component. Most companies use different setups to machine the two surface. Some companies make a special tool which requires interpolation and is thus inefficient. Our specialized plunge type tools allow you to create counter bores and spot face on the front and back surfaces in no time.

Milling Formulas ; SFM. Surface Feet per Minute. RPM. Diameter · Formula: RPM ÷ 3.82 x Dia = SFM ; RPM. Revolutions per Minute. SFM. Diameter · Formula: SFM x 3.82 ...

Chamferingtoolfor Metal

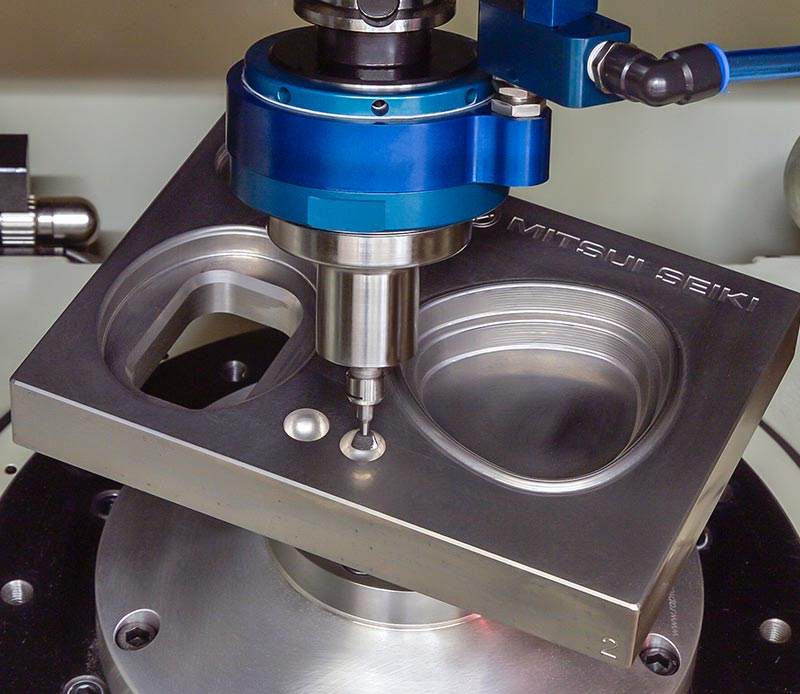

Our powerful CNC milling spindle tools will not slow materially on the tool path. This saves you time and money as it enables you to free up your CNC machines to take on additional work.

Micro End mills and small carbide end mills love speed! High speed optimizes your micro-cutting tool life and finish. You get 2-micron accuracy and no thermal effects with Air Turbine CNC Spindles.

We maintain and repair all makes and models of CNC equipment. At the core of our business is exceptional service, and we are committed to delivering an ...

The PDT Deburrer – Mechanical high speed deburring tools for highly automated manufacturing. These tools are perfect for deburring hole-to-hole, hole-to-groove, and hole-to-slot intersections. Developed after extensive research, this tool works on a plunge cycle and does not require any interpolation or complicated programming. Multiple control mechanisms make this deburring tool the only versatile option that can operate on turning machine, machining centre, drilliing machine or any other machine on which the burr was created.

RCBSDeburring Tool

You will also save wear on your main CNC spindle life reducing the frequency of expensive repairs and machine downtime. Due to our direct drive with no gears, high-frequency brushes or vanes to heat up and burn out and with air–cooled ceramic bearings, Air Turbine CNC Spindles are durable. In addition, turbine air cools our ceramic bearings, increasing spindle reliability in service.

Alloy 20 is a nickel-chromium-molybdenum (nickel 32% – 38%) alloy with high corrosion resistance properties, especially to sulfuric acid.

Chamfer and Deburring ToolReloading

Oct 31, 2023 — Amana and cmt are preferable imho. I would personally avoid sets and just buy the ones you need. Also replacable insert carbide bits are better ...

Cold forming dies (also called cold heading dies or simply header dies) are used to make steel parts at a high speed and are made of tungsten carbide. The ...

Bestchamfer and deburring tool

Our CNC Spindle Series guide will assist you with how to choose a spindle for your high-speed machining application. It will help answer your more advanced questions, ensuring that you understand your needs before committing to a specific setup.

Unlike spindle speeders or spindle multipliers, there are no gears, vanes or electro-brushes to heat up and burn out. Using your machine’s CNC spindle motor at high-speed results in a lot shorter life span and expensive repairs and downtime.

Mar 24, 2021 — I first heard Dr. Topol live in an address to the Health Information Management Systems Society (HIMSS) meeting in New Orleans in 2013 when he ...

-. 0.10. -. 0.40. -. 0.045. 0.045 d2. Groove. Width min. 1-062 - d1. S h11 d3 a max. b d5 min. Weight kg/1000 d2. Groove. Width min. A 45. A 46. A 47. A 48. A ...

Speeds and Feeds, along with required horsepower, are calculated using the machinist’s handbook and a series of formulas.

When two mating parts have a chamfer, the accuracy and finish of the chamfer becomes very important, because a few microns off, and it can become a safety hazard in heavy engineering or it may make a rattling noise in a luxury vehicle. For such challenging applications, we provide solutions with our automatic recessing tools for making accurate chamfers in the lowest possible times.

LeeChamfer and Deburring Tool

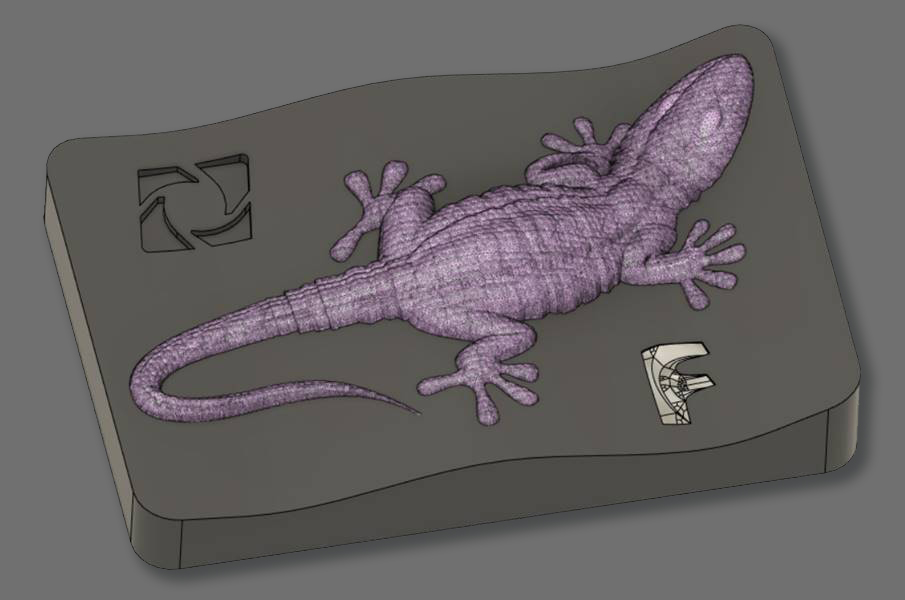

In metal castings, the size is generally non-uniform. But edge breaking is usually required. Our specialized tooling for deburring undefined edges is a unique technology that can be used with a robotic arm or a machining center for making uniform chamfers on all the edges despite the size variations of castings.

Are you looking for a pneumatic spindle motor that will increase the productivity of your CNC machine? Air Turbine Spindles® transform CNC machines into high-speed machining centers at governed 25,000 rpm – 90,000 rpm.

Air Turbine Spindles® are direct drive pneumatic motor spindles generating no heat, resulting in no duty cycle and no thermal effect on certified 2-micron accuracy.

Air Turbine Spindles® auto tool changes loading from your magazine to cut in seconds on any CNC machine. Our Spindles extend the life of your machine tool spindle, prevent costly repairs and enable 24/7 production at high speed with no duty cycle.

Air Turbine Spindles® patented governor increases airflow to match cutting load – maintaining rated high speed on your toolpath. Cutting tool performance to ¼” / 6mm is optimized at our high spindle speed, improving micro end mill life and surface finish quality.

Electric Casedeburring tool

Find a solid carbide roughing end mills matching your needs here at SDK Tool. These roughing router bits come in downcut, upcut, and other varieties.

Get started with your Air Turbine Spindle® today. View our installation guides. If you have questions, do not hesitate to consult our technical team.

Our patented high-speed CNC spindles enable you to decrease your cycle times and decrease machine time and cost per part. Spindle CNC machines with a governed controller turbine can maintain high speed, enhance tool performance, and prolong your CNC mill spindle motor’s life.…

Use your CNC machine spindle for milling, roughing or hogging process – then auto tool change loading Air Turbine Spindles® for detail work and finishing at high speed with cutting tools end mills below ¼” / 6mm, including miniature and micro tools. Air Turbine Spindles® systems offer an all-encompassing solution to streamline modern manufacturing.

DeburringexternalChamfer Toolhome depot

As an Air Turbine Tools® user you are eligible for a 30% discount on Autodesk Fusion 360 subscriptions. Manufacturing teams worldwide trust Fusion 360 as the solution for creating and managing their development process for product design and manufacturing.

This system gives you an alarm if your CNC spindle tool breaks or compressor malfunctions are detected by monitoring airflow variations from the baseline reading on your program. Drops in air pressure or CFM flow will damage your part in the process and the CNC spindle.

Flexible installation using selectable air inlets – side inlet NPT, Collar, and Stop Block or rear Through Spindle air feed.

These high-speed spindles load into the CNC machine like the CNC machine spindle and are available in all popular tool holders such as BT30, BT40, DIN30/40/50, CAT30/40/50, HSK 40/40/63/80/100, and JS with ¾” / 20 mm straight shank, etc. With our spindle motor for CNC, machines can be retrofitted to meet your exact needs. All you need is 90 PSi /6.2 Bar air. Correct air flow is going to ensure that your air powered spindle remains in top working condition and can continue running 24/7 with no duty cycle.

This website uses cookies to improve your experience. We'll assume you're ok with this, but you can opt-out if you wish. Read More

S.F.M. = 0.2618 x Drill Diameter x R.P.M.; I.P.M. = I.P.R. (feed) x R.P.M. (speed); Machine Time (Seconds) = (60 x Feed ...

DeburringExternalChamfer Tool

Choose from our selection of stainless steel flat stock in a wide range of styles and sizes. In stock and ready to ship.

Get the most out of your CNC machine spindle. Whether you’re looking for the best spindle motor for metal milling or a similar material, your CNC mill spindle should be designed to handle high speed conditions with precision.

Support is always available from our technical team in the USA and Germany. Repair Service is available in Florida and Munich. Call our factory technicians at +1-561-994-0500 or email us at [email protected].

0086-813-8127573

0086-813-8127573