Product Introduction

attachment:Carbide Turning Inserts for High Temperature Alloy.docx

Carbide Turning Inserts for High-Temperature Alloys

Company Profile

Zigong Xili Tool Co., Ltd was found in 2013; it is located in Zigong Bancang Industrial Park, the national high-tech zone of Zigong City, Sichuan Province. The company is committed to the research and development of new materials cutting tool, production of carbide turning inserts, milling inserts, boring inserts, grooving inserts, special shape inserts, customized inserts and other carbide products.

The company has a complete cemented carbide production line, processing line and inspection line. After years of ongoing development and accumulation, it has gained a good reputation in the industry owing to its excellent quality and professional service.

In recent years, the company develops rapidly, expands more market, enlarges production capacity and updates equipments. Especially, it has made a breakthrough in the research and development of cermet tools.

Adhering to the philosophy of “Honesty in life, practical work”, the company will continuously provide superior products and perfect services to customers from domestic and abroad.

Certificate

Production Flow

Quality Control:

We go through a 6-level strict quality control system

1.Carbide inspection after pressing

2.Quality inspection after sintering

3.Quality inspection after sintering

4.Quality inspection after coating

5.Quality inspection after coating

6.Quality inspection before shipping

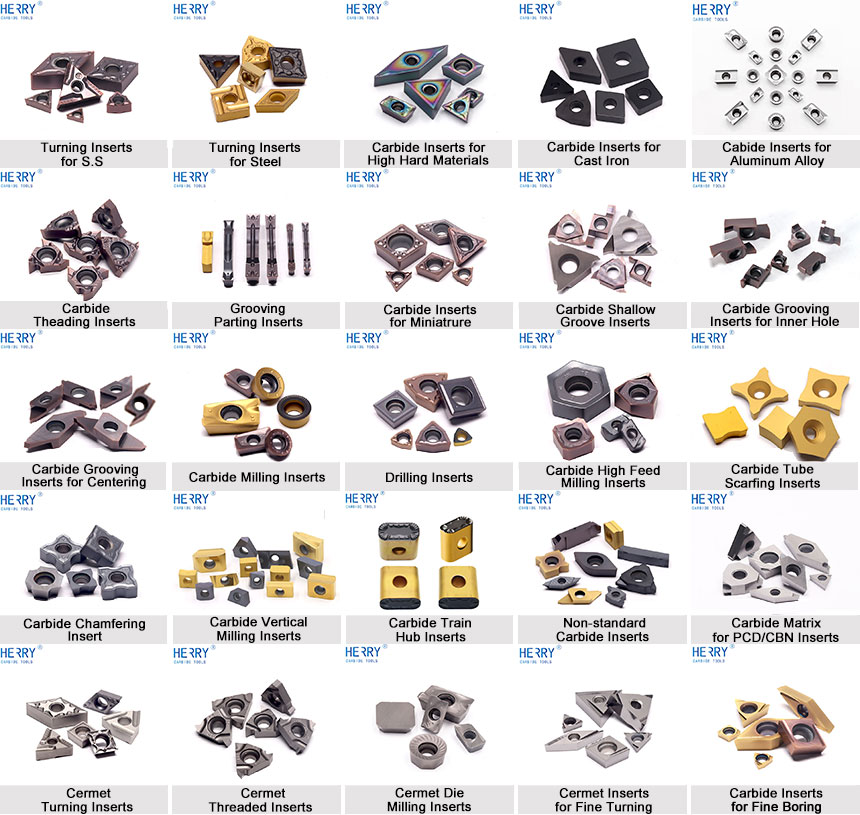

Our Main Products

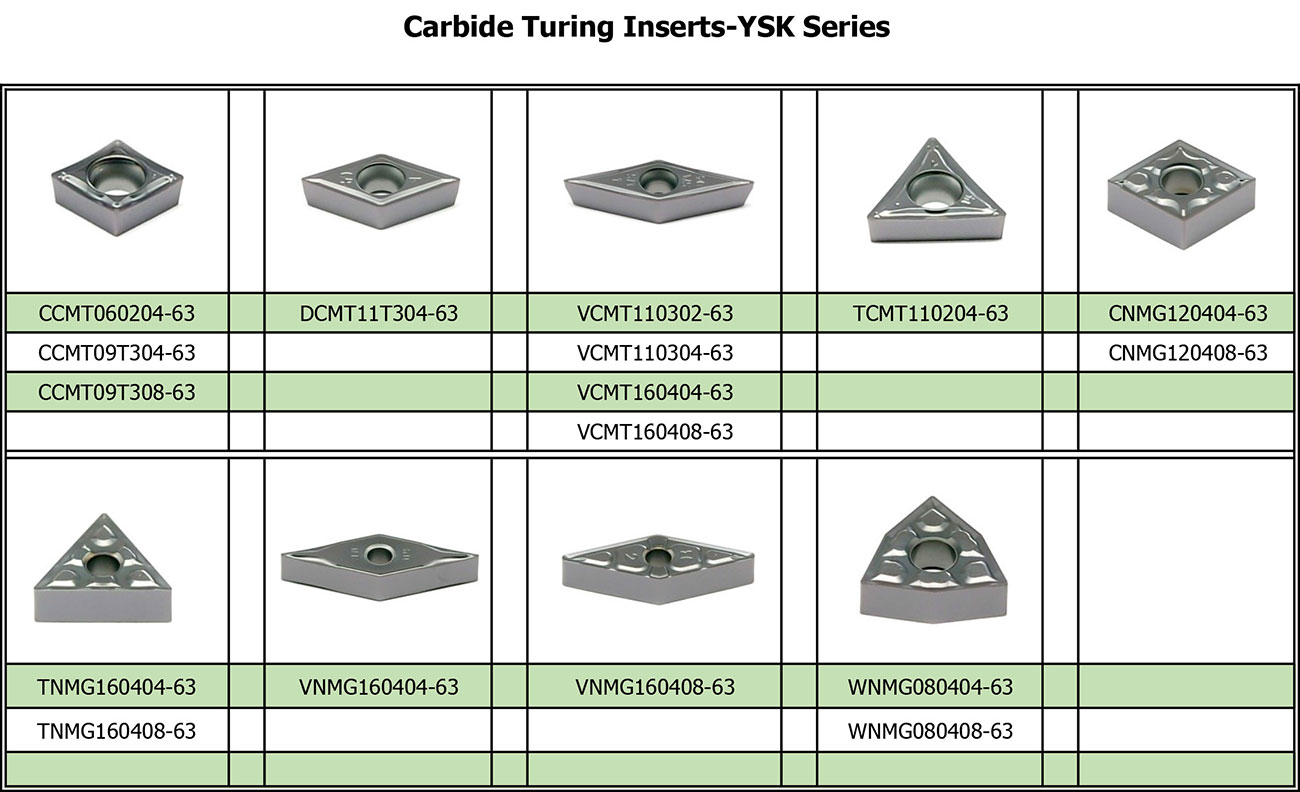

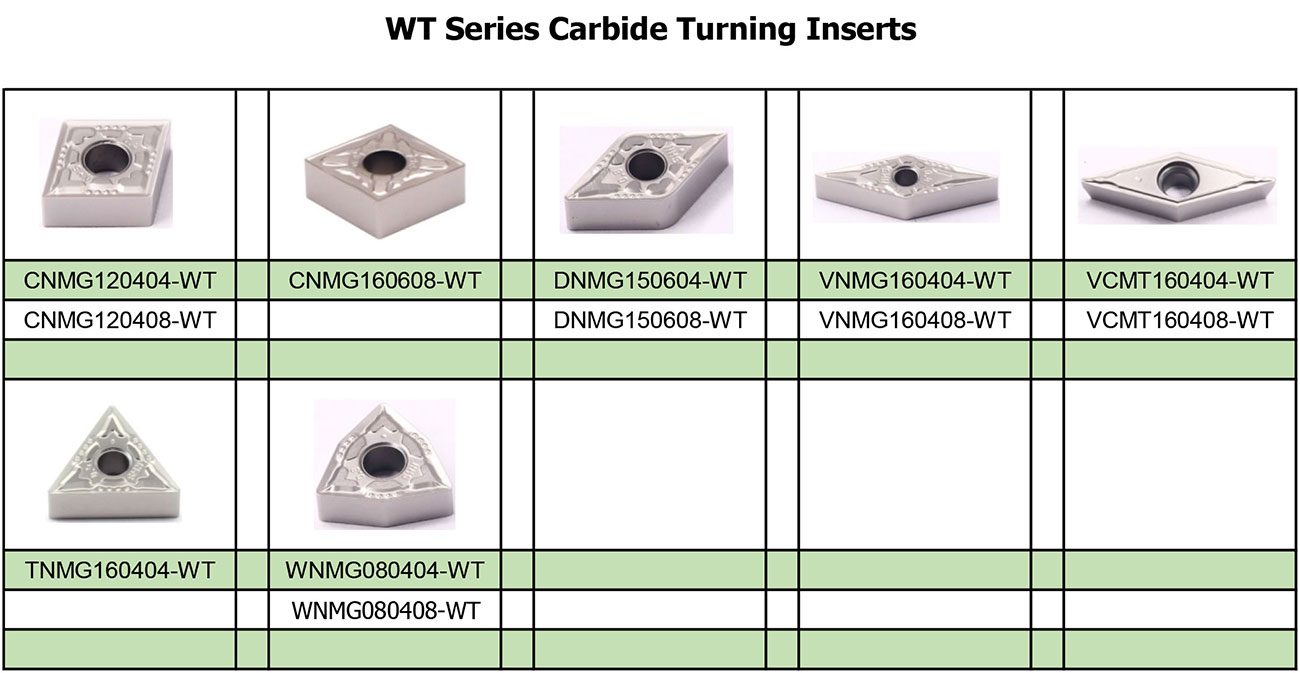

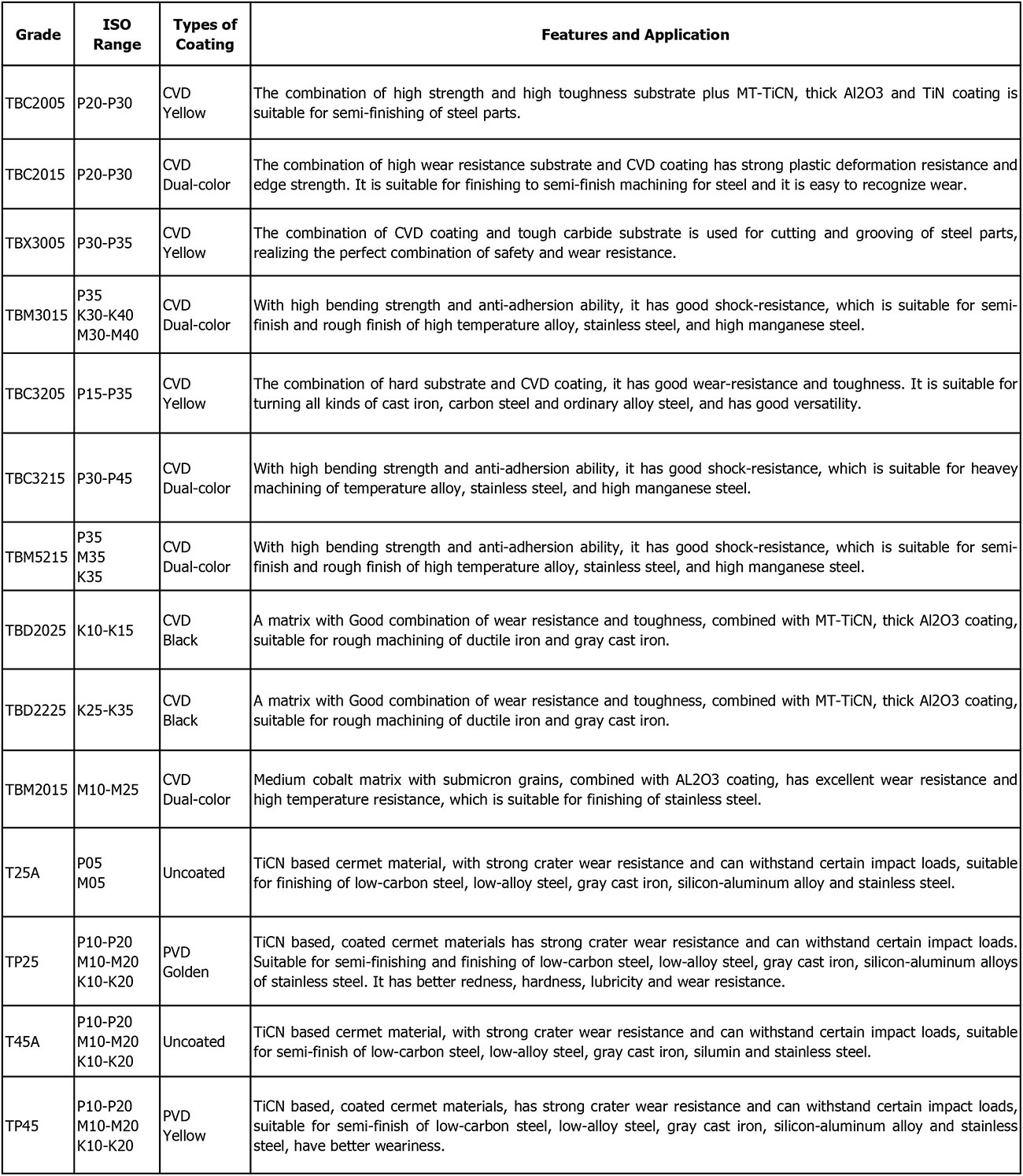

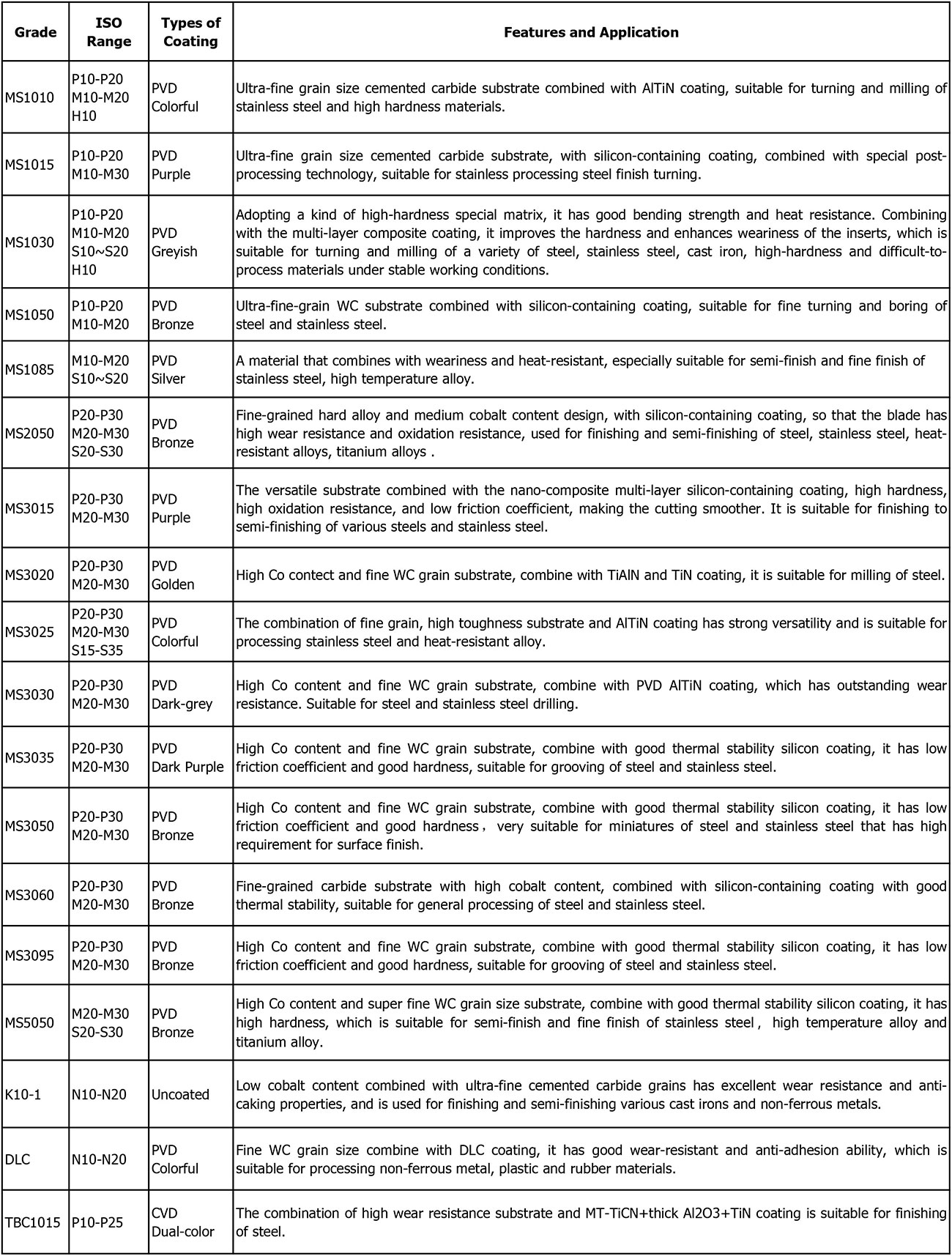

Carbide turning inserts

Carbide milling inserts

Carbide grooving parting inserts

Carbide drilling inserts

Carbide threading inserts

Carbide heavy milling inserts

Carbide vertical milling inserts

Carbide special purpose inserts

Customized carbide inserts

Cermet turning inserts

Cermet fine turning inserts

Cermet precision boring inserts

Carbide end mills

Carbide rotary burrs

Besides standard inserts, we can also make special shape and customized inserts.

Main Application:

Steel, carbon steel, alloy steel, tool steel, structure steel

Stainless steel

Cast iron

High temperature alloy

Non-ferrous metal, aluminum alloy, bronze

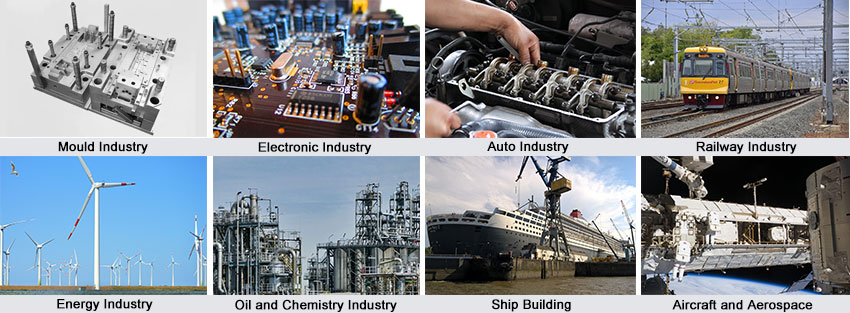

Served Industries:

Mould industry, railway industry, auto industry, electronic industry, oil and chemistry industry, energy industry, aircraft and aerospace industry, ship building industry, etc.

Packing and Shipping

We usually ship by express. And for big volume, we can also ship by air or by sea.

DHL: 5~7 working days

FedEx: 5~7 working days

TNT: 7~10 working days

UPS: 5~9 working days

EMS: 15~30 working days

Payment

We accept Western Union, Visa, Credit Card and bank T/T, etc.

FAQ:

Q: Are you trading company or manufacture?

A: We are factory. Our factory is located in Zigong city, Sichuan province, the main base of carbide products, we produce various carbide turning inserts, milling inserts, grooving inserts, threading inserts, non-standard special inserts and cermet inserts and other cutting tools like end mills, rotary burrs, etc.. Welcome to visit our factory.

Q: How long is your delivery time?

A: Generally it is 2~3 for ready stock, 10~45 days for production, and it also depends on the items (shape, size, and quantity) you need.

Q: Can you provide sample? Is it free or charged?

A: Yes, we can offer sample, whether sample will be charged or not depends on quantity. And buyers please kindly bear the courier cost.

Q: What is your minimum order requirement?

A: We accept the small trial order. And big order will get a big discount. And OEM orders are acceptable. Please contact for more details.

Conatact Information:

Zigong Xili CNC Tool Co.,LTD.

Add: 19-6 Longxiang Avenue, Bancang Industrial Park,High-tech Zone, Zigong City, Sichuan Province, China, 643000

Tel: 0086-813-8127573

Fax: 0086-813-5100787

WhatsApp: 0086 18581906093

Wechat: bonnieguo0602

Send Inquiry

18581906093

18581906093